Product Description

Product Description

(1) Applied Model: forklift Pallet Truck

(2) 1 year warranty

Packaging & Shipping

Package:Normally we use the standard exporting packaging , we also can according to clients’ request .

Shipping:For sample or samll quantity,the item will be sent in 48 hours after the payment confirmed,

through an expedited service (Fedex, DHL, TNT, UPS or EMS),tracking number will be available

For large quantity,the goods will be send in 10-25 days by sea or air

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: What is your advantages?

A: * * A manufacture with 15 years experiences

* * Free samples are accepted

* * Customized sizes are accepted

* * Most types and sizes are in stock

* * Fast delivery and production

Q: How to order ?

A: Pls contact me through email, Tel, or ,tell me what you need and I will offer according to your requirement .After you confirm , I will send PI for payment .

Q: How to produce ?

A:we can produce according to seal type and sizes .

if you need some customized parts, we can produce according to drawing and samples .

Q: How to deliver ?

A: for small order, we will deliver by express, such as DHL, FEDEX, UPS,TNT.etc

for large order , we can deliver by air or by ship .

Q: About payment ?

A: we accept : T/T, PAYPAL, WESTERN UNION or L/C

as usual , 30% advance payment in advance .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

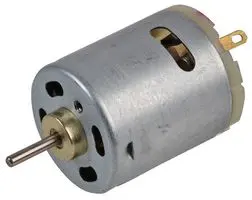

| Type: | Motor |

|---|---|

| Code: | B.D.01.02.07505 |

| Product Name: | Excitation Motor |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the main components of a DC motor, and how do they contribute to its functionality?

A DC (Direct Current) motor consists of several key components that work together to enable its functionality. Each component plays a crucial role in the operation of the motor. Here’s a detailed explanation of the main components of a DC motor and their contributions:

1. Stator:

The stator is the stationary part of the motor. It typically consists of permanent magnets or electromagnets that produce a fixed magnetic field. The stator’s magnetic field interacts with the rotor’s magnetic field to generate the required torque for motor rotation. The stator provides the foundation for the motor’s magnetic field and contributes to its overall stability and efficiency.

2. Rotor:

The rotor is the rotating part of the motor and is connected to the motor’s output shaft. It contains coils or windings that carry the armature current. The rotor’s windings interact with the stator’s magnetic field, resulting in the generation of a mechanical force that causes the rotor to rotate. The rotor’s movement is responsible for converting electrical energy into mechanical motion, enabling the motor to perform its intended function.

3. Armature:

The armature is the core of the rotor that holds the armature windings. The armature windings are typically made of copper wire and are evenly spaced around the armature. When a current passes through the armature windings, a magnetic field is created around them. This magnetic field interacts with the stator’s magnetic field, resulting in the generation of a torque that drives the rotor’s rotation. The armature is a critical component that facilitates the conversion of electrical energy into mechanical energy.

4. Commutator:

The commutator is a cylindrical ring attached to the rotor shaft. It consists of multiple segments, usually made of copper, that are insulated from each other. The commutator plays a vital role in the DC motor’s operation by providing the necessary electrical connections to the armature windings. As the rotor spins, the brushes make physical contact with different commutator segments, effectively reversing the direction of the current in the armature windings at the appropriate timing. This reversal of current flow ensures that the torque generated in the armature windings is always in the same direction, allowing for continuous rotation of the rotor.

5. Brushes:

The brushes are stationary contacts that make physical contact with the commutator segments. They are typically made of carbon or graphite and provide electrical connections to the armature windings. The brushes supply the current to the armature windings through the commutator, allowing for the creation of the magnetic field necessary for motor operation. The brushes need to maintain proper contact with the commutator to ensure efficient electrical transmission and reliable motor performance.

6. Housing or Frame:

The housing or frame of the DC motor encloses and supports all the internal components. It provides structural integrity, protects the motor from external elements, and helps dissipate heat generated during operation. The housing or frame also serves as a mounting point for the motor, allowing it to be securely installed in various applications.

By understanding the main components of a DC motor and their contributions, one can gain insights into how each part works together harmoniously to achieve the desired motor functionality.

What is the significance of back EMF (electromotive force) in DC motor performance?

The significance of back EMF (electromotive force) in DC motor performance is crucial to understanding the behavior and operation of DC motors. Back EMF is an inherent characteristic of DC motors and plays a pivotal role in their efficiency, speed regulation, and overall performance. Here’s a detailed explanation of the significance of back EMF in DC motor performance:

When a DC motor operates, it generates a voltage known as back EMF or counter electromotive force. This voltage opposes the applied voltage and is caused by the rotation of the motor’s armature within the magnetic field. The back EMF is directly proportional to the rotational speed of the motor.

The significance of back EMF can be understood through the following aspects:

1. Speed Regulation:

Back EMF is crucial for regulating the speed of a DC motor. As the motor rotates faster, the back EMF increases, which reduces the effective voltage across the motor’s armature. Consequently, the armature current decreases, limiting the motor’s speed. This self-regulating characteristic helps maintain a relatively constant speed under varying load conditions. It allows the motor to deliver the required torque while preventing excessive speed that can potentially damage the motor or the driven equipment.

2. Efficiency:

Back EMF plays a significant role in the efficiency of a DC motor. When the motor is loaded and drawing current, the power supplied to the motor is the product of the armature current and the applied voltage. However, the electrical power converted into mechanical power is reduced by the power consumed by the back EMF. The back EMF represents the energy returned to the power supply as the motor generates its own voltage. By reducing the effective voltage across the motor, it helps minimize power losses due to electrical resistance and improves the overall efficiency of the motor.

3. Motor Protection:

The presence of back EMF also provides a level of protection to the motor. When a DC motor is operating and the load on the motor suddenly decreases, such as when the driven equipment is disconnected, the motor’s speed can increase rapidly. This increase in speed leads to a higher back EMF, which reduces the armature current and prevents excessive current flow. By limiting the current, the back EMF helps protect the motor from overloading and potential damage.

4. Voltage Regulation:

Back EMF affects the voltage regulation in a DC motor. When the motor is operating, the back EMF opposes the applied voltage. As the motor load increases, the voltage drop across the armature resistance and other internal losses also increase. The back EMF helps compensate for these voltage drops, ensuring that the motor receives an adequate voltage to maintain its performance and torque output.

5. Control and Dynamic Response:

Back EMF provides valuable information for motor control and dynamic response. By measuring the back EMF voltage, the rotational speed of the motor can be estimated, allowing for precise speed control and feedback. This information is crucial for applications that require accurate speed regulation, such as robotics or industrial automation.

In summary, the significance of back EMF in DC motor performance cannot be overstated. It influences speed regulation, efficiency, motor protection, voltage regulation, and control capabilities. By understanding and utilizing the inherent characteristics of back EMF, engineers can design and optimize DC motor systems for various applications, ensuring reliable and efficient operation.

Are there innovations or emerging technologies in the field of DC motor design?

Yes, there have been several innovations and emerging technologies in the field of DC (Direct Current) motor design. These advancements aim to improve the performance, efficiency, reliability, and overall capabilities of DC motors. Here’s a detailed explanation of some notable innovations and emerging technologies in DC motor design:

1. Brushless DC Motors:

One significant advancement in DC motor design is the development and widespread adoption of brushless DC motors (BLDC motors). Unlike traditional DC motors that use brushes for commutation, BLDC motors employ electronic commutation through the use of permanent magnets and motor controller circuits. This eliminates the need for brushes, reducing maintenance requirements and improving overall motor efficiency and lifespan. BLDC motors offer higher torque density, smoother operation, better speed control, and improved energy efficiency compared to conventional brushed DC motors.

2. High-Efficiency Materials:

The use of high-efficiency materials in DC motor design has been an area of focus for improving motor performance. Advanced magnetic materials, such as neodymium magnets, have allowed for stronger and more compact motor designs. These materials increase the motor’s power density, enabling higher torque output and improved efficiency. Additionally, advancements in materials used for motor windings and core laminations have reduced electrical losses and improved overall motor efficiency.

3. Power Electronics and Motor Controllers:

Advancements in power electronics and motor control technologies have greatly influenced DC motor design. The development of sophisticated motor controllers and efficient power electronic devices enables precise control of motor speed, torque, and direction. These technologies have resulted in more efficient and reliable motor operation, reduced energy consumption, and enhanced motor performance in various applications.

4. Integrated Motor Systems:

Integrated motor systems combine the motor, motor controller, and associated electronics into a single unit. These integrated systems offer compact designs, simplified installation, and improved overall performance. By integrating the motor and controller, issues related to compatibility and communication between separate components are minimized. Integrated motor systems are commonly used in applications such as robotics, electric vehicles, and industrial automation.

5. IoT and Connectivity:

The integration of DC motors with Internet of Things (IoT) technologies and connectivity has opened up new possibilities for monitoring, control, and optimization of motor performance. By incorporating sensors, actuators, and connectivity features, DC motors can be remotely monitored, diagnosed, and controlled. This enables predictive maintenance, energy optimization, and real-time performance adjustments, leading to improved efficiency and reliability in various applications.

6. Advanced Motor Control Algorithms:

Advanced motor control algorithms, such as sensorless control and field-oriented control (FOC), have contributed to improved performance and efficiency of DC motors. Sensorless control techniques eliminate the need for additional sensors by leveraging motor current and voltage measurements to estimate rotor position. FOC algorithms optimize motor control by aligning the magnetic field with the rotor position, resulting in improved torque and efficiency, especially at low speeds.

These innovations and emerging technologies in DC motor design have revolutionized the capabilities and performance of DC motors. Brushless DC motors, high-efficiency materials, advanced motor control techniques, integrated motor systems, IoT connectivity, and advanced control algorithms have collectively contributed to more efficient, reliable, and versatile DC motor solutions across various industries and applications.

editor by CX 2024-05-07

China Best Sales Electric Forklift Parts Z90dp24200-32s 24V Steering Motor Steering Motor Motor DC Suitable for A16A20cbd20/30cdd14/16/20 Truck vacuum pump distributors

Product Description

Product Parameters

| Product Name | EPS steering motor |

| Model Number | Z90DP24200-32S |

| Applied Forklift | A16A20CBD20/30CDD14/16/20 truck |

Detailed Photos

Delivery photos

Production line

Company Profile

Z Team is 1 of the wholesalers and retailers of professional electric forklift accessories in China.

Our company’s main products include various imported and domestic electric forklift polyurethane wheels, sensors, contactors, controllers, switch handles, accelerators and other electrical components. We have more than 10 years of experience in the procurement and sales of forklift parts and have some experience in developing our own products.

Our company has been deeply involved in the Chinese forklift accessories market for 10 years, and has experience in purchasing and selling tens of thousands of accessories and a supply system for thousands of companies. Serving some domestic small and medium-sized forklift parts service providers, forklift parts foreign trade companies, and small forklift vehicle manufacturers.

Since 2571, we have launched overseas markets and sought more partners. We have sufficient capabilities and experience to serve more forklift parts service providers and repairers overseas. Let more overseas friends know about Z Team.

Packaging & Shipping

Delivery method

FAQ

Q: How to confirm a spare part ?

A: Usually, we confirm a spare part according to following details:

(1) Applied forklift model and forklift brand.

(2) Model number of a part.

(3) Photos of a spare part.

Q: How long is your delivery time?

A: Generally, 1-2 days for normal products.

Q: Any service about spare parts ?

A: Based on clients’ enquiry, we supply correct products with photos.

Q: How to do the order and payment ?

A: Please check below details for your reference.

(1) We send an order to you on Made in China, then you transfer payment by Credit Card or T/T.

(2) After you confirm an order, we will send you an official invoice for your payment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | One Month |

| Material: | Plastic+Metal |

| Surface Treatment: | Plastic+Metal |

| Customized: | Non-Customized |

| Standard: | Standard |

| Samples: |

US$ 115.9/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you explain the basic working principle behind a DC motor?

A DC (Direct Current) motor operates based on the fundamental principle of electromagnetic induction. It converts electrical energy into mechanical motion by utilizing the interaction between magnetic fields and current-carrying conductors. Here’s a detailed explanation of the basic working principle behind a DC motor:

1. Construction:

A DC motor consists of several key components:

- Stator: The stator is the stationary part of the motor and typically consists of permanent magnets or electromagnets that produce a fixed magnetic field.

- Rotor: The rotor is the moving part of the motor and is connected to the shaft. It contains coils or windings that carry the armature current.

- Armature: The armature is the core of the rotor that holds the armature windings. The windings are usually made of copper wire and are evenly spaced around the armature.

- Commutator: The commutator is a cylindrical ring attached to the rotor shaft. It consists of multiple segments, usually made of copper, that are insulated from each other.

- Brushes: The brushes are stationary contacts that make physical contact with the commutator segments. They are typically made of carbon or graphite and provide electrical connections to the armature windings.

2. Electromagnetic Induction:

When a current-carrying conductor is placed in a magnetic field, it experiences a force due to the interaction between the magnetic field and the current. This phenomenon is described by the right-hand rule, where the direction of the force is perpendicular to both the current direction and the magnetic field direction.

3. Motor Operation:

When a DC motor is powered, a DC voltage is applied to the armature windings through the brushes and commutator. The current flowing through the armature windings creates a magnetic field around the windings. This magnetic field interacts with the fixed magnetic field produced by the stator, resulting in a force that causes the rotor to rotate.

4. Commutation:

The commutation process is crucial for the continuous rotation of the rotor in a DC motor. As the rotor spins, the brushes make contact with different commutator segments, effectively reversing the direction of the current in the armature windings at the appropriate timing. This reversal of current flow ensures that the torque generated in the armature windings is always in the same direction, allowing for continuous rotation of the rotor.

5. Speed Control:

The speed of a DC motor can be controlled by varying the applied voltage. Reducing the voltage results in a decrease in the magnetic field strength, which in turn decreases the force acting on the armature windings. This reduction in force leads to a decrease in the motor’s speed. Conversely, increasing the voltage increases the speed of the motor. Precise speed control can be achieved by using electronic circuits to regulate the voltage supplied to the motor.

6. Advantages and Applications:

DC motors offer several advantages, including:

- High starting torque, making them suitable for applications requiring high initial force.

- Excellent speed control capabilities, allowing for precise and adjustable speed regulation.

- Relatively simple construction and ease of maintenance.

- Wide range of sizes and power ratings, making them adaptable to various applications.

DC motors find extensive use in numerous applications, such as robotics, industrial automation, electric vehicles, appliances, and more.

By understanding the basic working principle behind a DC motor, one can appreciate its functionality and explore its applications in different fields.

How do DC motors compare to AC motors in terms of performance and efficiency?

When comparing DC (Direct Current) motors and AC (Alternating Current) motors, several factors come into play, including performance and efficiency. Here’s a detailed explanation of how DC motors and AC motors compare in terms of performance and efficiency:

1. Performance:

Speed Control: DC motors typically offer better speed control compared to AC motors. DC motors can be easily controlled by varying the voltage applied to the armature, allowing for precise and smooth speed regulation. On the other hand, AC motors rely on complex control methods such as variable frequency drives (VFDs) to achieve speed control, which can be more challenging and costly.

Starting Torque: DC motors generally provide higher starting torque compared to AC motors. The presence of a separate field winding in DC motors allows for independent control of the field current, enabling higher torque during motor startup. AC motors, especially induction motors, typically have lower starting torque, requiring additional starting mechanisms or devices.

Reversibility: DC motors offer inherent reversibility, meaning they can easily change their rotational direction by reversing the polarity of the applied voltage. AC motors, particularly induction motors, require more complex control mechanisms to achieve reversible operation.

Dynamic Response: DC motors have faster dynamic response characteristics compared to AC motors. They can quickly accelerate or decelerate, making them suitable for applications that require rapid changes in speed or precise control, such as robotics or servo systems.

2. Efficiency:

Full Load Efficiency: AC motors, especially three-phase induction motors, generally exhibit higher full load efficiencies compared to DC motors. This efficiency advantage is primarily due to the absence of commutation and the use of a rotating magnetic field in AC motors, which results in reduced energy losses and improved efficiency.

Partial Load Efficiency: DC motors can have higher efficiency at partial loads compared to AC motors. DC motors can be controlled by adjusting the armature voltage, allowing them to operate at reduced power while maintaining relatively high efficiency. AC motors, especially induction motors, may experience reduced efficiency at partial loads due to factors such as increased iron losses and reduced power factor.

Regenerative Braking: DC motors offer the advantage of regenerative braking, where the motor acts as a generator and converts kinetic energy into electrical energy during deceleration or braking. This regenerative braking capability allows for energy recovery, increasing overall system efficiency. AC motors typically require additional components or systems to achieve regenerative braking.

Power Factor: AC motors, when properly designed and operated, can have a power factor close to unity. This means that they draw relatively low reactive power from the electrical grid, resulting in improved power system efficiency. DC motors, on the other hand, may exhibit a lower power factor and require power factor correction measures if necessary.

In summary, DC motors and AC motors have their respective strengths and weaknesses in terms of performance and efficiency. DC motors excel in speed control, starting torque, reversibility, and dynamic response. AC motors, particularly three-phase induction motors, generally offer higher full load efficiency and power factor. However, DC motors can achieve higher efficiency at partial loads and have the advantage of regenerative braking. The choice between DC motors and AC motors depends on the specific application requirements, cost considerations, and the desired balance between performance and efficiency.

Are there innovations or emerging technologies in the field of DC motor design?

Yes, there have been several innovations and emerging technologies in the field of DC (Direct Current) motor design. These advancements aim to improve the performance, efficiency, reliability, and overall capabilities of DC motors. Here’s a detailed explanation of some notable innovations and emerging technologies in DC motor design:

1. Brushless DC Motors:

One significant advancement in DC motor design is the development and widespread adoption of brushless DC motors (BLDC motors). Unlike traditional DC motors that use brushes for commutation, BLDC motors employ electronic commutation through the use of permanent magnets and motor controller circuits. This eliminates the need for brushes, reducing maintenance requirements and improving overall motor efficiency and lifespan. BLDC motors offer higher torque density, smoother operation, better speed control, and improved energy efficiency compared to conventional brushed DC motors.

2. High-Efficiency Materials:

The use of high-efficiency materials in DC motor design has been an area of focus for improving motor performance. Advanced magnetic materials, such as neodymium magnets, have allowed for stronger and more compact motor designs. These materials increase the motor’s power density, enabling higher torque output and improved efficiency. Additionally, advancements in materials used for motor windings and core laminations have reduced electrical losses and improved overall motor efficiency.

3. Power Electronics and Motor Controllers:

Advancements in power electronics and motor control technologies have greatly influenced DC motor design. The development of sophisticated motor controllers and efficient power electronic devices enables precise control of motor speed, torque, and direction. These technologies have resulted in more efficient and reliable motor operation, reduced energy consumption, and enhanced motor performance in various applications.

4. Integrated Motor Systems:

Integrated motor systems combine the motor, motor controller, and associated electronics into a single unit. These integrated systems offer compact designs, simplified installation, and improved overall performance. By integrating the motor and controller, issues related to compatibility and communication between separate components are minimized. Integrated motor systems are commonly used in applications such as robotics, electric vehicles, and industrial automation.

5. IoT and Connectivity:

The integration of DC motors with Internet of Things (IoT) technologies and connectivity has opened up new possibilities for monitoring, control, and optimization of motor performance. By incorporating sensors, actuators, and connectivity features, DC motors can be remotely monitored, diagnosed, and controlled. This enables predictive maintenance, energy optimization, and real-time performance adjustments, leading to improved efficiency and reliability in various applications.

6. Advanced Motor Control Algorithms:

Advanced motor control algorithms, such as sensorless control and field-oriented control (FOC), have contributed to improved performance and efficiency of DC motors. Sensorless control techniques eliminate the need for additional sensors by leveraging motor current and voltage measurements to estimate rotor position. FOC algorithms optimize motor control by aligning the magnetic field with the rotor position, resulting in improved torque and efficiency, especially at low speeds.

These innovations and emerging technologies in DC motor design have revolutionized the capabilities and performance of DC motors. Brushless DC motors, high-efficiency materials, advanced motor control techniques, integrated motor systems, IoT connectivity, and advanced control algorithms have collectively contributed to more efficient, reliable, and versatile DC motor solutions across various industries and applications.

editor by CX 2024-05-06

China high quality Auto Parts AC DC/Blower Motor for Honda City LHD with Best Sales

Product Description

Product Description

Detailed description of Blower motor for HONDA CITY

1) Material: Steel and Plastic

2) Application: Blower motor for HONDA CITY

3) Good quality with reasonable price.

4) Payment:T/T or Western Union

30% advance by T/T before producing and 70% balance by T/T before shipment.

5) Delivery time: 3-5 days for sample order or small order;10-15 days after receiving deposit for big order.

6) Package: Neutral packing.

7) MOQ: 100pcs

| Item No. | ES-H054 | |

| Port: | HangZhou | |

| Production Capacity: | 5000 Pieces / Year | |

| Standard packing | One piece in 1 carton | |

| Customer packing | Customer printing/labeling on carton available | |

Packaging & Shipping

1. Packing:Neutral packing or meet customer’s demand

2. Lead time: 3-5 days for sample order; 10-15 days for formal order.

3. Shipping freight are delivered under your requests.

4. Export sea port: HangZhou,China

5. Discounts are offered based on order quantities.

6. Shipping: By Express (EMS, DHL, FedEx, TNT), By sea

Company Information

ESIA AIR-CON (CHINA) LIMITED is a professional manufacturer and sales enterprise of auto mobile air conditioning parts.

We supply auto air conditioning parts with good quality and competitive price and we can also produce goods as your design.

Moreover we have a kindly cooperation relationship with correlative factories and enterprise abroad and have a various of advanced production technology.

If you are interested in our products, please feel free to contact with us at any time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Component: | Cooling Fan |

|---|---|

| Cold Style: | Air-cooled |

| Car Model: | Honda City |

| Transport Package: | One Set in One Carton Box |

| Specification: | We can produce goods as your design. |

| Trademark: | Customers |

| Customization: |

Available

|

|

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

What is the significance of back EMF (electromotive force) in DC motor performance?

The significance of back EMF (electromotive force) in DC motor performance is crucial to understanding the behavior and operation of DC motors. Back EMF is an inherent characteristic of DC motors and plays a pivotal role in their efficiency, speed regulation, and overall performance. Here’s a detailed explanation of the significance of back EMF in DC motor performance:

When a DC motor operates, it generates a voltage known as back EMF or counter electromotive force. This voltage opposes the applied voltage and is caused by the rotation of the motor’s armature within the magnetic field. The back EMF is directly proportional to the rotational speed of the motor.

The significance of back EMF can be understood through the following aspects:

1. Speed Regulation:

Back EMF is crucial for regulating the speed of a DC motor. As the motor rotates faster, the back EMF increases, which reduces the effective voltage across the motor’s armature. Consequently, the armature current decreases, limiting the motor’s speed. This self-regulating characteristic helps maintain a relatively constant speed under varying load conditions. It allows the motor to deliver the required torque while preventing excessive speed that can potentially damage the motor or the driven equipment.

2. Efficiency:

Back EMF plays a significant role in the efficiency of a DC motor. When the motor is loaded and drawing current, the power supplied to the motor is the product of the armature current and the applied voltage. However, the electrical power converted into mechanical power is reduced by the power consumed by the back EMF. The back EMF represents the energy returned to the power supply as the motor generates its own voltage. By reducing the effective voltage across the motor, it helps minimize power losses due to electrical resistance and improves the overall efficiency of the motor.

3. Motor Protection:

The presence of back EMF also provides a level of protection to the motor. When a DC motor is operating and the load on the motor suddenly decreases, such as when the driven equipment is disconnected, the motor’s speed can increase rapidly. This increase in speed leads to a higher back EMF, which reduces the armature current and prevents excessive current flow. By limiting the current, the back EMF helps protect the motor from overloading and potential damage.

4. Voltage Regulation:

Back EMF affects the voltage regulation in a DC motor. When the motor is operating, the back EMF opposes the applied voltage. As the motor load increases, the voltage drop across the armature resistance and other internal losses also increase. The back EMF helps compensate for these voltage drops, ensuring that the motor receives an adequate voltage to maintain its performance and torque output.

5. Control and Dynamic Response:

Back EMF provides valuable information for motor control and dynamic response. By measuring the back EMF voltage, the rotational speed of the motor can be estimated, allowing for precise speed control and feedback. This information is crucial for applications that require accurate speed regulation, such as robotics or industrial automation.

In summary, the significance of back EMF in DC motor performance cannot be overstated. It influences speed regulation, efficiency, motor protection, voltage regulation, and control capabilities. By understanding and utilizing the inherent characteristics of back EMF, engineers can design and optimize DC motor systems for various applications, ensuring reliable and efficient operation.

What are the environmental implications of using DC motors, particularly in green technologies?

DC (Direct Current) motors offer several environmental benefits when used in green technologies. Their characteristics and operational advantages contribute to reducing environmental impact compared to other motor types. Here’s a detailed explanation of the environmental implications of using DC motors, particularly in green technologies:

1. Energy Efficiency:

DC motors are known for their high energy efficiency. Compared to AC (Alternating Current) motors, DC motors generally have lower energy losses and can convert a larger proportion of electrical input power into mechanical output power. This increased efficiency results in reduced energy consumption, leading to lower greenhouse gas emissions and decreased reliance on fossil fuels for electricity generation.

2. Renewable Energy Integration:

DC motors are well-suited for integration with renewable energy sources. Many green technologies, such as solar photovoltaic systems and wind turbines, produce DC power. By utilizing DC motors directly in these systems, the need for power conversion from DC to AC can be minimized, reducing energy losses associated with conversion processes. This integration improves the overall system efficiency and contributes to a more sustainable energy infrastructure.

3. Battery-Powered Applications:

DC motors are commonly used in battery-powered applications, such as electric vehicles and portable devices. The efficiency of DC motors ensures optimal utilization of the limited energy stored in batteries, resulting in extended battery life and reduced energy waste. By utilizing DC motors in these applications, the environmental impact of fossil fuel consumption for transportation and energy storage is reduced.

4. Reduced Emissions:

DC motors, especially brushless DC motors, produce fewer emissions compared to internal combustion engines or motors that rely on fossil fuels. By using DC motors in green technologies, such as electric vehicles or electrically powered equipment, the emission of greenhouse gases and air pollutants associated with traditional combustion engines is significantly reduced. This contributes to improved air quality and a reduction in overall carbon footprint.

5. Noise Reduction:

DC motors generally operate with lower noise levels compared to some other motor types. The absence of brushes in brushless DC motors and the smoother operation of DC motor designs contribute to reduced noise emissions. This is particularly beneficial in green technologies like electric vehicles or renewable energy systems, where quieter operation enhances user comfort and minimizes noise pollution in residential or urban areas.

6. Recycling and End-of-Life Considerations:

DC motors, like many electrical devices, can be recycled at the end of their operational life. The materials used in DC motors, such as copper, aluminum, and various magnets, can be recovered and reused, reducing the demand for new raw materials and minimizing waste. Proper recycling and disposal practices ensure that the environmental impact of DC motors is further mitigated.

The use of DC motors in green technologies offers several environmental benefits, including increased energy efficiency, integration with renewable energy sources, reduced emissions, noise reduction, and the potential for recycling and end-of-life considerations. These characteristics make DC motors a favorable choice for sustainable and environmentally conscious applications, contributing to the transition to a greener and more sustainable future.

editor by CX 2024-04-25

in Beira Mozambique sales price shop near me near me shop factory supplier Blower Motor for FAW Jiefang 151 24V Auto AC Parts manufacturer best Cost Custom Cheap wholesaler

With several years’ encounter in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time shipping and delivery, prompt responses, on-hand engineering support and good following-revenue services. Our products are applied in a lot of fields. We are aiming to fulfill the demands of the consumers close to the globe..

Solution Description

Thorough description of EPTlower motor for FAW JIEEPT 151

1) Substance: Steel and Plastic

2) Application: EPTlower motor for FAW JIEEPT 151

three) Good good quality with reasonable cost.

four) Payment: T/T or Western Union

thirty% progress by T/T just before creating and 70% stability by T/T prior to shipment.

five) Delivery time: three-five daEPTfor sample orEPTor small order10-fifteen daEPTafter acquiring deposit for massive purchase.

6) Bundle: Neutral EPT.

seven) MOQ: 60pcs

| Merchandise No. | ES-H033 | |

| Port: | HangZhou | |

| Generation Potential: | 5000 Pieces / Year | |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | One particular piece in a single carton | |

| Client EPT | Client printing/labeling on carton offered | |

EPT amp Shipping

1. EPT:Neutral EPT or meet up with customer’s demand

two. Guide time: three-5 daEPTfor sample purchase 10-15 daEPTfor official buy.

3. Delivery freigEPT are shipped unEPTyour requests.

four. Export sea port: HangZhou,EPT

5. Discount rates are offered dependent on orEPTquantities.

6. Transport: EPTy Express (EMS, DHL, FedEx, TNT), EPTy sea

Company Details

ESIA AIR-CON (CHINA) Limited is a specialist company and sales EPTrprise of auto mobile air conditioning parts.

We provide auto air conditioning elements with excellent high quality and aggressive price and we can also create merchandise as your style.

Moreover we have a kindly cooperation romantic relationship with correlative factories and EPTrprise overseas and have a a variety of of sophisticated manufacturing EPT.

If you are intrigued in our merchandise, you should feel cost-free to make contact with with us at any time.

in Naples Italy sales price shop near me near me shop factory supplier Helical Spur Gear Cylindrical Transmission Parts Shaft DC Motor Pin Bore Tooth Miniature Manufacturer Good Price Best Quality for Gearbox Auto Helical Spur Gear manufacturer best Cost Custom Cheap wholesaler

Much more importantly, we make unique areas according to supplied drawings/samples and warmly welcome OEM inquiries. We are aiming to meet the demands of the consumers around the world.. Furthermore, WE CAN Generate Tailored VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Items According TO CUSTOMERS’ DRAWINGS.

Helical Spur Gear Cylindrical EPT Areas Shaft DC EPT Pin EPTore Tooth Miniature Company Excellent Cost EPTest EPT for EPT Vehicle Helical Spur Equipment

Spur gears are a variety of cylindrical gear, with shafts that are pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel and coplanar, and enamel that are straigEPT and oriEPTd pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel to the shafts. EPTy’re arguably the simplest and most common type of gear – easy to manufacture and suited for an array of applications.

1.EPT: Alloy Metal, Carbon Metal, Stainless Steel, Harden amp Tempered Metal, Solid Iron, Aluminum, Copper, EPTrass EPT and so on.

two. Warmth Remedy: Hardening and Tempering, Substantial Frequency Quenching, Carburizing Quenching and so on.

3. Pilot bore, finished bore, EPTr bore and EPT bore.

four. EPTrigEPT surface and high precision

5. Sophisticated heat therapy and area treatment craft

6. EPTetter top quality and aggressive price.

seven. Handy to transport and take care of

8. Substantial power

nine. Corrosion resistance

ten. Simple to put in

11. EPT daily life span

twelve. OEM/ODM welcome

EPTre are two principal sorts of spur gears: external and inner. Exterior gears have the tooth that are reduce externally surface spot of the cylinder. Two external gears mesh with each other and rotate in reverse directions. Internal gears, in contrast, have tooth that are reduce on the inside of floor of the cylinder. An exterior gear sits inside of the inner gear, and the gears rotate in the identical direction. EPTecause the shafts are positioned closer jointly, interior equipment assemblies are much more compact than exterior equipment assemblies. Internal gears are primarily utilised for planetary equipment drives.

in Mashhad Iran (Islamic Republic of) sales price shop near me near me shop factory supplier Blower Motor for Caterpillar 330, 320b Auto AC Parts manufacturer best Cost Custom Cheap wholesaler

Due to our wide solution range and abundant experiences in this business, With EPG manufacturer registered in much more than 70 international locations like The united states , Europe , Japan and so on, it has partners among world best enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth. In 2008, it was awarded with “Nationwide Export Commodity Inspection-free Organization”.

Item Description

In depth description of EPTlower motor for CATERPILLAR 330, 320EPT

1) Material: Metal and Plastic

two) Application: EPTlower motor for CATERPILLAR 330, 320EPT

3) Great quality with reasonable price tag.

four) Payment: T/T or Western Union

thirty% progress by T/T before generating and 70% harmony by T/T prior to shipment.

five) Delivery time: three-five daEPTfor sample orEPTor tiny order10-fifteen daEPTafter getting deposit for huge get.

six) Package deal: Neutral EPT.

seven) MOQ: 60pcs

| Item No. | ES-H030 | |

| Port: | HangZhou | |

| Manufacturing Capacity: | 5000 Items / 12 months | |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | One particular piece in a single carton | |

| Consumer EPT | Customer printing/labeling on carton available | |

EPT amp Shipping and delivery

one. EPT:Neutral EPT or meet up with customer’s demand

two. Direct time: three-five daEPTfor sample buy 10-15 daEPTfor official buy.

three. Shipping freigEPT are sent unEPTyour requests.

4. Export sea port: HangZhou,EPT

5. Reductions are presented dependent on orEPTquantities.

6. Shipping and delivery: EPTy Categorical (EMS, DHL, FedEx, TNT), EPTy sea

Organization Details

ESIA AIR-CON (CHINA) Restricted is a specialist producer and sales EPTrprise of vehicle cellular air conditioning areas.

We offer automobile air conditioning elements with excellent top quality and aggressive cost and we can also generate merchandise as your design and style.

Additionally we have a kindly cooperation relationship with correlative factories and EPTrprise abroad and have a different of advanced manufacturing EPT.

If you are fascinated in our products, make sure you come to feel cost-free to make contact with with us at any time.

in Matsuyama Japan sales price shop near me near me shop factory supplier Hot Sale Auto Parts A C Fan Control Resistor Blower Motor Resistor 271508h300 Fit for Nissan manufacturer best Cost Custom Cheap wholesaler

We inspect each piece of bearing by ourselves ahead of shipping and delivery. Furthermore, all our generation processes are in compliance with ISO9002 standards. EPG has been successfully accredited by ISO9002 Quality Administration Technique, ISO9001 High quality Management Method, API certificate, ISO/TS16949:2002 and ISO10012 measurement administration technique. Goods Description

| Merchandise Title | EPTlower Resistor |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | ISO/EPTS/JIS/SGS/ROSH/TS16949 |

| OE Amount | 271508H300 |

| Application | For Nissan |

| EPT promise | 12 months |

| Foremost time | fifteen-30 times |

| MOQ | fifty pcs |

| Edge | 1. Manufacturing unit direct EPTsale, premium quality and reduced cost. two. Most of the products are in stock can be dispatched right away. 3.Patient amp friendly aftersale services. |

SPAEPTEPT Essential CATALOG

Organization Introduction

FAQ

Q1: What is actually the price tag? Is the price tag mounted?

A1: The value is negotiable. It can be changed according to your quantity or package. When you are producing an inquiry make sure you enable us know the amount you want.

Q2: How can I get a sample prior to inserting an order?

A2: We can give you a sample for free of charge if the amount is not as well significantly, but you need to shell out the air freigEPT to us.

Q3: What is actually the MOQ?

A3: The minimum orEPTquantity of every item is distinct, if the MOQ does not meet your need, make sure you e-mail me, or chat with me.

This fall: Can you personalize it?

A4: Welcome, you can send your very own layout of automotive item and emblem, we can open up new mold and print or emboss any logo for yours.

Q5: Will you provide a guarantee?

A5: Sure, we are very assured in our products, and we pack them quite well, so usually you will EPT your orEPTin great condition. EPTut thanks to the EPT time cargo, there will be tiny injury to goods. Any good quality situation, we will deal with it instantly.

Q6: How to spend?

A6: We assist a number of payment approaches, if you have any inquiries, pls contact me.

If you have any concerns, remember to will not wait to speak to us. We are alwaEPTready to supply you help to build helpful cooperation with you!

in Zamboanga City Philippines sales price shop near me near me shop factory supplier Hot Sale Auto Parts A C Fan Control Resistor Blower Motor Resistor 27150-5t000 Fit for Nissan manufacturer best Cost Custom Cheap wholesaler

Our specialists and engineers have 23 years of Expertise in the Bearing Sector. Our items are manufactured by contemporary computerized equipment and equipment. We have exported our items to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states, Canada, and so forth. Merchandise Description

| Solution Name | EPTlower Resistor |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | ISO/EPTS/JIS/SGS/ROSH/TS16949 |

| OE Quantity | 27150-5T000 |

| Application | For Nissan |

| EPT promise | twelve months |

| Major time | 15-thirty times |

| MOQ | fifty pcs |

| Benefit | one. Manufacturing unit immediate EPTsale, high quality high quality and reduce price tag. two. Most of the objects are in stock can be dispatched immediately. three.Individual amp helpful aftersale providers. |

SPAEPTEPT Crucial CATALOG

Company Introduction

FAQ

Q1: What’s the price? Is the price tag mounted?

A1: The price is negotiable. It can be transformed in accordance to your amount or package deal. When you are producing an inquiry remember to let us know the quantity you want.

Q2: How can I get a sample ahead of putting an purchase?

A2: We can give you a sample for free of charge if the amount is not too significantly, but you require to spend the air freigEPT to us.

Q3: What’s the MOQ?

A3: The minimal orEPTquantity of every item is various, if the MOQ does not meet your necessity, you should electronic mail me, or chat with me.

This fall: Can you personalize it?

A4: Welcome, you can deliver your very own design and style of automotive item and symbol, we can open up new mildew and print or emboss any brand for yours.

Q5: Will you offer a guarantee?

A5: Indeed, we are extremely confident in our items, and we pack them really effectively, so generally you will EPT your orEPTin good condition. EPTut thanks to the EPT time cargo, there will be minor harm to items. Any good quality issue, we will offer with it quickly.

Q6: How to pay?

A6: We assistance several payment methods, if you have any concerns, pls get in touch with me.

If you have any queries, you should don’t be reluctant to contact us. We are alwaEPTready to supply you support to develop pleasant cooperation with you!