Product Description

Why choose CHINAMFG Factory ?

♦ CHINAMFG is the only double certified enterprise by German TUV IATF16949 & ISO9001 in the pump industry

♦ 16 years of industry experience.Independent research and development, national high-tech enterprise, multiple domestic and foreign invention patents

♦ Annual production capacity of 3,008,000 pieces

♦ 4 laboratories that meeting the CNAS certification standard

♦ 80% of the products are exported to high-end market in Europe and America

Remarks:

– We are High-end Brushless DC pumps Manufacturer. Can provide customized services

– If you are interested in our products, pls feel free to contact us

Customer Reviews

WRAS approved Big flow high pressure Quiet Pumped Electric Shower pump

Φ Advanced magnetic driving technology for static-seal,without any leakage forever

Φ Heavy duty work,can sustain continuous 24hours work

Φ High efficiency ECM brushless DC motor with long lifetime 25,000hours

Φ 3-phase motor for lower power consumption and lower fever

Φ Durable permanent magnetic rotor/impeller and fine ceramic shaft

Φ Specializing closed-type impeller for lower water loss bring higher efficiency

Φ High temperature materials for liquid temperature ≥100°C

Φ Low or no maintenance

Φ Food grade materials

Φ Imported Japan XYRON PPE material, certificated by WRAS .

Specification

| Model | Product Code | Max Water Flow (L/Min) | Rated Voltage(DC) | Rated Current (A) | Max Water Head(M) | Rated Power(W) | Speed (RPM) |

|

| C01 | TL-C01-A12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | |

| TL-C01-B12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-C12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-D12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-A12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-B12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-C12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-D12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-A24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-B24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-C24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-D24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5530 | ||

| TL-C01-A24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-B24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-C24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-D24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

|

(customized functions) 1.PWM, 0~5V speed control, |

||||||||

| Motor | High performance 3-phase motor | ||||||

| 12V Highest operating voltage | 18V | ||||||

| 12V Starting voltage | 6V | ||||||

| 24V Highest operating voltage | 28V | ||||||

| 24V Starting voltage | 12V | ||||||

| Working rated | Continuous | ||||||

| Noise | ≤45dB(A) from 1M Distance | ||||||

| Coil Insulation class | Class F | ||||||

| Media | Water, antifreeze,other | ||||||

| Power Supply | DC power supply, battery, solar powered | ||||||

| Remarks | Can’t dry-running, not Self-priming | ||||||

| The technical parameters above is only for your reference, for more details , please feel free to contact us. | |||||||

1. Liquid transfer general purpose pumping 2. Hot water circulating system

3. Electronics Cooling Water Circulation Chiller Systems

4. Liquid filling and transfer in food, beverage processing, vending machines

5. Instant electric water heater, electric shower.

6. Circulating systems for homes, RV’s and boats

7. Cleaning equipment, purification and water treatment.

8. Irrigation solar pump, swimming pool circulation 9. Electric cars: radiators, heaters

Get more information, Please Send Message

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Max.Head: | 8m 11m |

|---|---|

| Max.Capacity: | 18L 20L 22L |

| Driving Type: | Magnetic |

| Material: | Imported PPE |

| Structure: | Single-stage Pump |

| Assembly: | Booster Pump |

| Samples: |

US$ 28/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

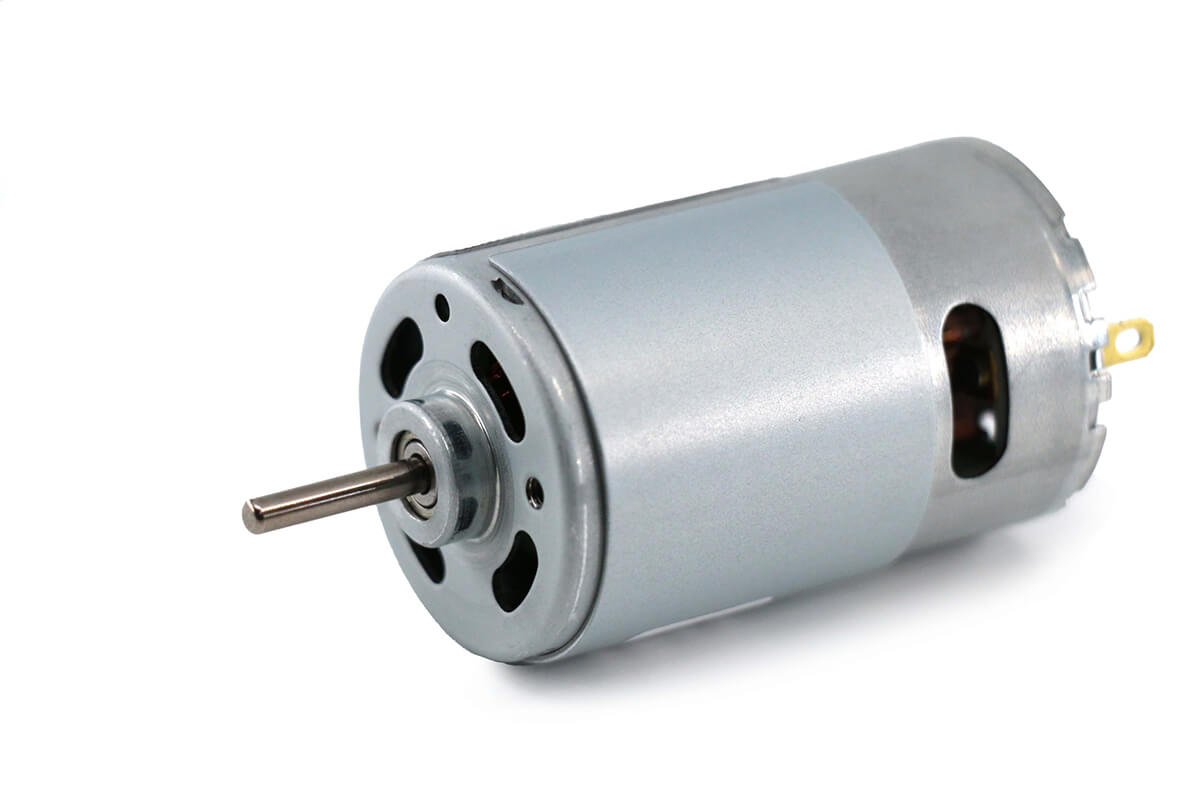

What is a DC motor, and how does it differ from other types of electric motors?

A DC (Direct Current) motor is an electric motor that converts electrical energy into mechanical motion. It operates based on the principle of electromagnetic induction and the interaction between current-carrying conductors and magnetic fields. DC motors are widely used in various applications due to their simplicity, controllability, and versatility. Here’s a detailed explanation of what a DC motor is and how it differs from other types of electric motors:

1. Basic Operation:

In a DC motor, electrical energy is supplied to the motor’s armature through a DC power source, typically a battery or a rectified power supply. The armature consists of multiple coils or windings that are evenly spaced around the motor’s rotor. The rotor is a cylindrical core with a shaft that rotates when the motor is energized. When current flows through the armature windings, it creates a magnetic field that interacts with the fixed magnetic field produced by the motor’s stator. This interaction generates a torque, causing the rotor to rotate.

2. Commutation:

DC motors employ a commutator and brushes for the conversion of electrical energy and the rotation of the rotor. The commutator consists of a segmented cylindrical ring attached to the rotor shaft, and the brushes are stationary conductive contacts that make contact with the commutator segments. As the rotor spins, the brushes maintain contact with the commutator segments, periodically reversing the direction of the current flow in the armature windings. This reversal of current flow in the armature windings ensures continuous rotation of the rotor in the same direction.

3. Types of DC Motors:

DC motors can be classified into different types based on their construction and the method of field excitation. The two main types are:

- Brushed DC Motors: Brushed DC motors have a mechanical commutator and brushes to switch the current direction in the armature windings. These motors are relatively simple, cost-effective, and offer good torque characteristics. However, the commutator and brushes require regular maintenance and can generate electrical noise and brush wear debris.

- Brushless DC Motors (BLDC): Brushless DC motors, also known as electronically commutated motors (ECMs), use electronic circuits and sensors to control the current flow in the motor windings. They eliminate the need for brushes and commutators, resulting in reduced maintenance and improved reliability. BLDC motors offer higher efficiency, smoother operation, and better speed control compared to brushed DC motors.

4. Speed Control:

DC motors provide excellent speed control capabilities. By adjusting the voltage applied to the motor, the speed of the DC motor can be regulated. Lowering the voltage reduces the motor’s speed, while increasing the voltage increases the speed. This feature makes DC motors suitable for applications that require precise speed control, such as robotics, conveyor systems, and electric vehicles.

5. Advantages and Disadvantages:

DC motors have several advantages, including:

- Simple construction and easy maintenance (for brushed DC motors).

- High starting torque.

- Precise speed control.

- Good controllability over a wide range of loads.

However, DC motors also have some limitations, such as:

- Brushed DC motors require periodic maintenance and have limited brush life.

- Brushed DC motors can generate electrical noise.

- Brushless DC motors are often more expensive compared to brushed DC motors.

6. Differences from Other Electric Motors:

DC motors differ from other types of electric motors, such as AC (Alternating Current) motors, in several ways:

- Power Source: DC motors require a DC power source, while AC motors operate from an AC power supply.

- Speed Control: DC motors offer precise speed control by adjusting the applied voltage, whereas AC motors typically rely on frequency control for speed regulation.

- Construction: DC motors use a commutator and brushes (in brushed DC motors) or electronic commutation (in brushless DC motors), while AC motors do not require commutation.

- Starting Torque: DC motors typically provide higher starting torque compared to AC motors.

Overall, DC motors are versatile and widely used in various applications due to their controllability, speed regulation capabilities, and simplicity. The advancements inpower electronics and motor control technologies have further enhanced the performance and efficiency of DC motors, making them a popular choice in many industries.

How is the efficiency of a DC motor determined, and what factors can affect it?

In a DC (Direct Current) motor, efficiency refers to the ratio of the motor’s output power (mechanical power) to its input power (electrical power). It is a measure of how effectively the motor converts electrical energy into mechanical work. The efficiency of a DC motor can be determined by considering several factors that affect its performance. Here’s a detailed explanation of how the efficiency of a DC motor is determined and the factors that can influence it:

The efficiency of a DC motor is calculated using the following formula:

Efficiency = (Output Power / Input Power) × 100%

1. Output Power: The output power of a DC motor is the mechanical power produced at the motor’s shaft. It can be calculated using the formula:

Output Power = Torque × Angular Speed

The torque is the rotational force exerted by the motor, and the angular speed is the rate at which the motor rotates. The output power represents the useful work or mechanical energy delivered by the motor.

2. Input Power: The input power of a DC motor is the electrical power supplied to the motor. It can be calculated using the formula:

Input Power = Voltage × Current

The voltage is the electrical potential difference applied to the motor, and the current is the amount of electrical current flowing through the motor. The input power represents the electrical energy consumed by the motor.

Once the output power and input power are determined, the efficiency can be calculated using the formula mentioned earlier.

Several factors can influence the efficiency of a DC motor:

1. Copper Losses:

Copper losses occur due to the resistance of the copper windings in the motor. These losses result in the conversion of electrical energy into heat. Higher resistance or increased current flow leads to greater copper losses and reduces the efficiency of the motor. Using thicker wire for the windings and minimizing resistance can help reduce copper losses.

2. Iron Losses:

Iron losses occur due to magnetic hysteresis and eddy currents in the motor’s iron core. These losses result in the conversion of electrical energy into heat. Using high-quality laminated iron cores and minimizing magnetic flux variations can help reduce iron losses and improve efficiency.

3. Friction and Windage Losses:

Friction and windage losses occur due to mechanical friction between moving parts and air resistance. These losses result in the conversion of mechanical energy into heat. Proper lubrication, efficient bearing systems, and aerodynamically optimized designs can help minimize friction and windage losses.

4. Brush and Commutator Losses:

In brushed DC motors, brush and commutator losses occur due to the friction and electrical resistance at the brush-commutator interface. These losses result in the conversion of electrical energy into heat. Using high-quality brushes and commutators, reducing brush voltage drop, and minimizing the number of commutator segments can help reduce these losses.

5. Magnetic Field Design:

The design of the magnetic field in the motor significantly affects its efficiency. Optimizing the magnetic field for the specific application, such as selecting appropriate magnet materials or designing efficient electromagnets, can improve the motor’s efficiency.

6. Motor Load:

The load on the motor, including the torque and speed requirements, can impact its efficiency. Operating the motor close to its optimal load conditions or utilizing speed control techniques, such as pulse width modulation (PWM), can help improve efficiency by reducing unnecessary power consumption.

7. Motor Size and Construction:

The size and construction of the motor can influence its efficiency. Properly sizing the motor for the intended application and optimizing the design for reduced losses, improved cooling, and efficient heat dissipation can enhance overall efficiency.

It’s important to note that the efficiency of a DC motor is typically highest at or near its rated load conditions. Deviating significantly from the rated load can result in reduced efficiency.

In summary, the efficiency of a DC motor is determined by comparing the output power to the input power. Factors such as copper losses, iron losses, friction and windage losses, brush and commutator losses, magnetic field design, motor load, and motor size and construction can all influence the efficiency of a DC motor. By considering and optimizing these factors, the overall efficiency of the motor can be improved.

Where can individuals find reliable resources for learning more about DC motors and their applications?

Individuals seeking reliable resources to learn more about DC (Direct Current) motors and their applications can explore various sources that provide comprehensive and accurate information. Here’s a detailed explanation of where individuals can find reliable resources for learning about DC motors:

1. Manufacturer Websites:

Many DC motor manufacturers have dedicated sections on their websites that provide detailed information about their products, including specifications, application notes, technical guides, and whitepapers. These resources offer valuable insights into the design, operation, and application considerations of DC motors. Examples of reputable DC motor manufacturers include Baldor, Maxon Motor, and Faulhaber.

2. Industry Associations and Organizations:

Industry associations and organizations related to electrical engineering, automation, and motor technology can be excellent sources of reliable information. Examples include the Institute of Electrical and Electronics Engineers (IEEE) and the American Society of Mechanical Engineers (ASME). These associations often provide access to technical publications, research papers, conferences, and educational resources related to DC motors and their applications.

3. Technical Books and Publications:

Technical books and publications authored by experts in the field of electrical engineering and motor technology can provide in-depth knowledge about DC motors. Books such as “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and “Practical Electric Motor Handbook” by Irving Gottlieb are widely regarded as reliable resources for learning about DC motors and their applications.

4. Online Educational Platforms:

Online educational platforms offer a wealth of resources for learning about DC motors. Websites like Coursera, Udemy, and Khan Academy provide online courses, tutorials, and video lectures on electrical engineering, motor theory, and applications. These platforms often have courses specifically dedicated to DC motors, covering topics such as motor principles, control techniques, and practical applications.

5. Research Papers and Scientific Journals:

Research papers published in scientific journals and conference proceedings can provide detailed insights into the latest advancements and research findings related to DC motors. Platforms like IEEE Xplore, ScienceDirect, and Google Scholar can be used to search for scholarly articles on DC motors. These papers are authored by researchers and experts in the field and provide reliable and up-to-date information on various aspects of DC motor technology.

6. Online Forums and Communities:

Online forums and communities focused on electrical engineering, motor technology, and DIY projects can be valuable resources for learning about DC motors. Platforms like Reddit, Stack Exchange (Electrical Engineering section), and specialized motor forums provide opportunities to ask questions, engage in discussions, and learn from experienced individuals in the field. However, it’s important to verify information obtained from online forums as they may contain a mix of opinions and varying levels of expertise.

When accessing these resources, it’s essential to critically evaluate the information and cross-reference it with multiple sources to ensure accuracy and reliability. By utilizing a combination of manufacturer websites, industry associations, technical books, online educational platforms, research papers, and online communities, individuals can gain a comprehensive understanding of DC motors and their applications.

editor by CX 2024-05-07