Product Description

Hot Sales

Product Description

Highway centrifugal fan motor brushless high efficient outer rotor cooling fan AC DC motor air conditioner parts cooler fan motor

1. Stator size is optional

2. Safe, reliable, low noise, good starting, long life

3. Strong power

Rated voltage 5~120V/220~240V-50/60Hz

Typical used:

Exhaust fan, air purifier, micro-oven, fan, induction cooker, refrigerator, pump, heater, hood oven, blwer, air conditioner, Heater machines, dehumidifiers

Thermal protector with 1 shot fuse or multi shot fuse

Fan motor Production Flow

Company Profile

HangZhou HIGHWAY INDUSTRY COMPANY LIMITED is located in Xihu (West Lake) Dis. HangZhou, ZheJiang Province and was founded in 2004, which is a manufacturer for AC EC DC centrifugal fan, AC EC DC axial fan, and other cooling fans, integrating R&D, design, manufacturing and sales on intelligent small and medium fans. We have accumulated many years of motor R & D and manufacturing technology.

We have established external rotor fan products in the field of film-coated AC and DC, which is widely used in fresh air, air purification, electricity, mechanical equipment, new energy, telecommunications, HVAC, refrigeration, IT, communication and other fields.

HIGHWAY adhere to the “quality first, the customer first, reasonable prices, courteous service” principle, efforts to be a a green enterprise integrating technology leadership, resource conservation and eco-friendliness. Welcome the new old customers throughout the visit!

Work Shop

Testing Equipment

FAQ:

Question 1: Where is your factory?

Answer 1: Our factory is located in HangZhou, ZheJiang Province, which is nearby HangZhou or HangZhou. Warmly welcome you to visit us!

Question 2: Do you accept OEM?

Answer 2: Sure. Please tell us the information like fan type, quantity, size, material, voltage, air flow and static pressure, etc.

Question 3: What’s the payment terms?

Answer 3: T/T, other terms please contact us.

Question 4: How about the delivery time?

Answer 4: Normally 20 days after receiving deposit, detailed product period depends on the order.

Question 5: How can I get the quotation?

Answer 5: Feel free to contact us by TradeMessenger or Email. You will get reply within 24 hours.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Single-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

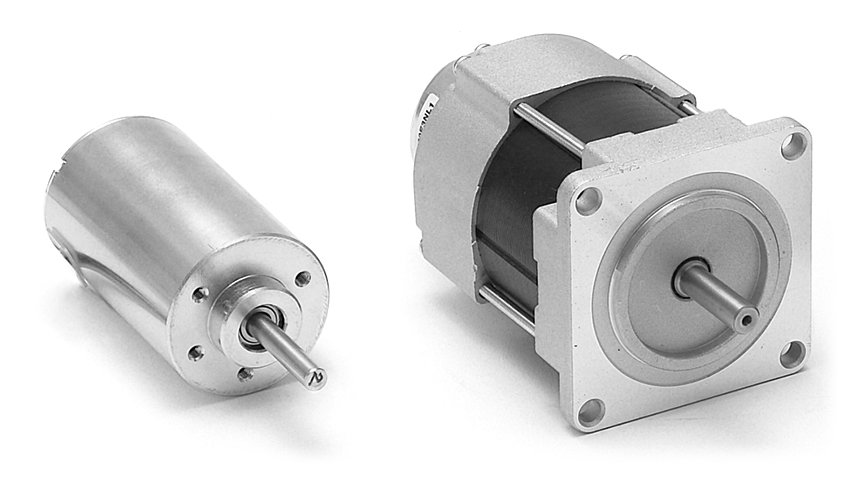

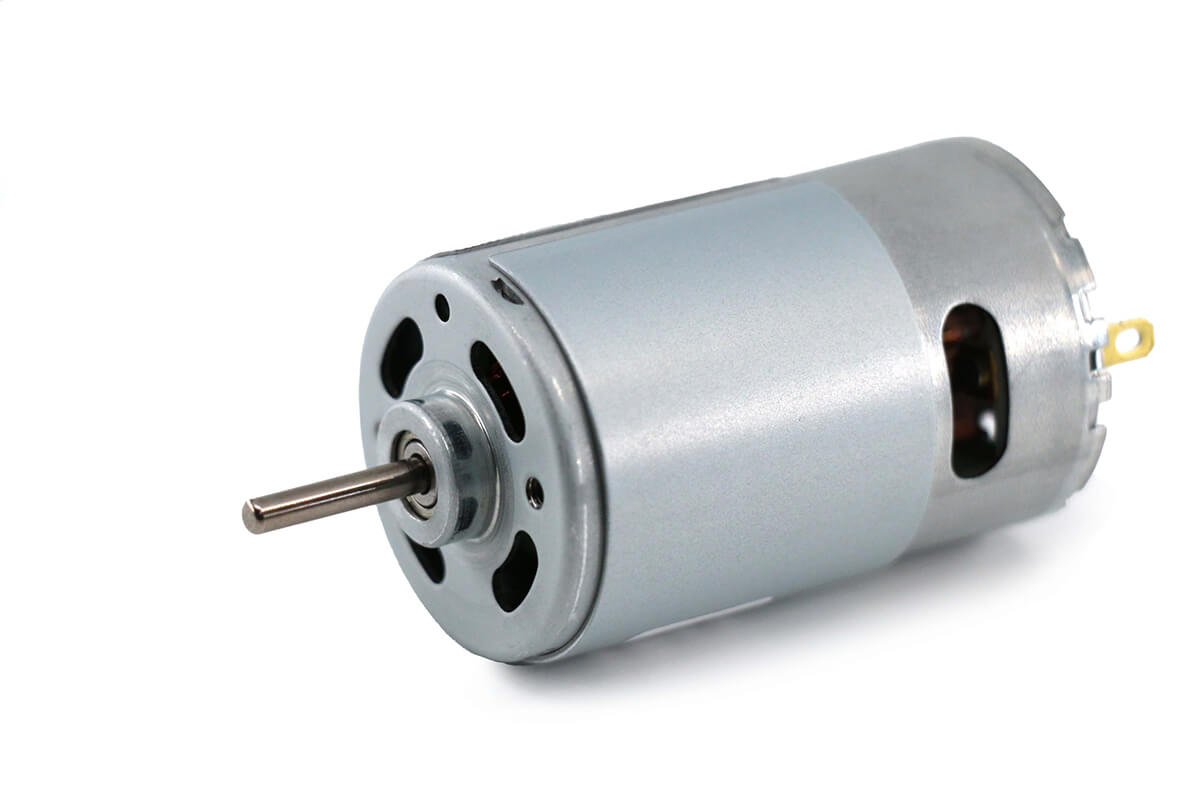

What is a DC motor, and how does it differ from other types of electric motors?

A DC (Direct Current) motor is an electric motor that converts electrical energy into mechanical motion. It operates based on the principle of electromagnetic induction and the interaction between current-carrying conductors and magnetic fields. DC motors are widely used in various applications due to their simplicity, controllability, and versatility. Here’s a detailed explanation of what a DC motor is and how it differs from other types of electric motors:

1. Basic Operation:

In a DC motor, electrical energy is supplied to the motor’s armature through a DC power source, typically a battery or a rectified power supply. The armature consists of multiple coils or windings that are evenly spaced around the motor’s rotor. The rotor is a cylindrical core with a shaft that rotates when the motor is energized. When current flows through the armature windings, it creates a magnetic field that interacts with the fixed magnetic field produced by the motor’s stator. This interaction generates a torque, causing the rotor to rotate.

2. Commutation:

DC motors employ a commutator and brushes for the conversion of electrical energy and the rotation of the rotor. The commutator consists of a segmented cylindrical ring attached to the rotor shaft, and the brushes are stationary conductive contacts that make contact with the commutator segments. As the rotor spins, the brushes maintain contact with the commutator segments, periodically reversing the direction of the current flow in the armature windings. This reversal of current flow in the armature windings ensures continuous rotation of the rotor in the same direction.

3. Types of DC Motors:

DC motors can be classified into different types based on their construction and the method of field excitation. The two main types are:

- Brushed DC Motors: Brushed DC motors have a mechanical commutator and brushes to switch the current direction in the armature windings. These motors are relatively simple, cost-effective, and offer good torque characteristics. However, the commutator and brushes require regular maintenance and can generate electrical noise and brush wear debris.

- Brushless DC Motors (BLDC): Brushless DC motors, also known as electronically commutated motors (ECMs), use electronic circuits and sensors to control the current flow in the motor windings. They eliminate the need for brushes and commutators, resulting in reduced maintenance and improved reliability. BLDC motors offer higher efficiency, smoother operation, and better speed control compared to brushed DC motors.

4. Speed Control:

DC motors provide excellent speed control capabilities. By adjusting the voltage applied to the motor, the speed of the DC motor can be regulated. Lowering the voltage reduces the motor’s speed, while increasing the voltage increases the speed. This feature makes DC motors suitable for applications that require precise speed control, such as robotics, conveyor systems, and electric vehicles.

5. Advantages and Disadvantages:

DC motors have several advantages, including:

- Simple construction and easy maintenance (for brushed DC motors).

- High starting torque.

- Precise speed control.

- Good controllability over a wide range of loads.

However, DC motors also have some limitations, such as:

- Brushed DC motors require periodic maintenance and have limited brush life.

- Brushed DC motors can generate electrical noise.

- Brushless DC motors are often more expensive compared to brushed DC motors.

6. Differences from Other Electric Motors:

DC motors differ from other types of electric motors, such as AC (Alternating Current) motors, in several ways:

- Power Source: DC motors require a DC power source, while AC motors operate from an AC power supply.

- Speed Control: DC motors offer precise speed control by adjusting the applied voltage, whereas AC motors typically rely on frequency control for speed regulation.

- Construction: DC motors use a commutator and brushes (in brushed DC motors) or electronic commutation (in brushless DC motors), while AC motors do not require commutation.

- Starting Torque: DC motors typically provide higher starting torque compared to AC motors.

Overall, DC motors are versatile and widely used in various applications due to their controllability, speed regulation capabilities, and simplicity. The advancements inpower electronics and motor control technologies have further enhanced the performance and efficiency of DC motors, making them a popular choice in many industries.

How do DC motors compare to AC motors in terms of performance and efficiency?

When comparing DC (Direct Current) motors and AC (Alternating Current) motors, several factors come into play, including performance and efficiency. Here’s a detailed explanation of how DC motors and AC motors compare in terms of performance and efficiency:

1. Performance:

Speed Control: DC motors typically offer better speed control compared to AC motors. DC motors can be easily controlled by varying the voltage applied to the armature, allowing for precise and smooth speed regulation. On the other hand, AC motors rely on complex control methods such as variable frequency drives (VFDs) to achieve speed control, which can be more challenging and costly.

Starting Torque: DC motors generally provide higher starting torque compared to AC motors. The presence of a separate field winding in DC motors allows for independent control of the field current, enabling higher torque during motor startup. AC motors, especially induction motors, typically have lower starting torque, requiring additional starting mechanisms or devices.

Reversibility: DC motors offer inherent reversibility, meaning they can easily change their rotational direction by reversing the polarity of the applied voltage. AC motors, particularly induction motors, require more complex control mechanisms to achieve reversible operation.

Dynamic Response: DC motors have faster dynamic response characteristics compared to AC motors. They can quickly accelerate or decelerate, making them suitable for applications that require rapid changes in speed or precise control, such as robotics or servo systems.

2. Efficiency:

Full Load Efficiency: AC motors, especially three-phase induction motors, generally exhibit higher full load efficiencies compared to DC motors. This efficiency advantage is primarily due to the absence of commutation and the use of a rotating magnetic field in AC motors, which results in reduced energy losses and improved efficiency.

Partial Load Efficiency: DC motors can have higher efficiency at partial loads compared to AC motors. DC motors can be controlled by adjusting the armature voltage, allowing them to operate at reduced power while maintaining relatively high efficiency. AC motors, especially induction motors, may experience reduced efficiency at partial loads due to factors such as increased iron losses and reduced power factor.

Regenerative Braking: DC motors offer the advantage of regenerative braking, where the motor acts as a generator and converts kinetic energy into electrical energy during deceleration or braking. This regenerative braking capability allows for energy recovery, increasing overall system efficiency. AC motors typically require additional components or systems to achieve regenerative braking.

Power Factor: AC motors, when properly designed and operated, can have a power factor close to unity. This means that they draw relatively low reactive power from the electrical grid, resulting in improved power system efficiency. DC motors, on the other hand, may exhibit a lower power factor and require power factor correction measures if necessary.

In summary, DC motors and AC motors have their respective strengths and weaknesses in terms of performance and efficiency. DC motors excel in speed control, starting torque, reversibility, and dynamic response. AC motors, particularly three-phase induction motors, generally offer higher full load efficiency and power factor. However, DC motors can achieve higher efficiency at partial loads and have the advantage of regenerative braking. The choice between DC motors and AC motors depends on the specific application requirements, cost considerations, and the desired balance between performance and efficiency.

Are there innovations or emerging technologies in the field of DC motor design?

Yes, there have been several innovations and emerging technologies in the field of DC (Direct Current) motor design. These advancements aim to improve the performance, efficiency, reliability, and overall capabilities of DC motors. Here’s a detailed explanation of some notable innovations and emerging technologies in DC motor design:

1. Brushless DC Motors:

One significant advancement in DC motor design is the development and widespread adoption of brushless DC motors (BLDC motors). Unlike traditional DC motors that use brushes for commutation, BLDC motors employ electronic commutation through the use of permanent magnets and motor controller circuits. This eliminates the need for brushes, reducing maintenance requirements and improving overall motor efficiency and lifespan. BLDC motors offer higher torque density, smoother operation, better speed control, and improved energy efficiency compared to conventional brushed DC motors.

2. High-Efficiency Materials:

The use of high-efficiency materials in DC motor design has been an area of focus for improving motor performance. Advanced magnetic materials, such as neodymium magnets, have allowed for stronger and more compact motor designs. These materials increase the motor’s power density, enabling higher torque output and improved efficiency. Additionally, advancements in materials used for motor windings and core laminations have reduced electrical losses and improved overall motor efficiency.

3. Power Electronics and Motor Controllers:

Advancements in power electronics and motor control technologies have greatly influenced DC motor design. The development of sophisticated motor controllers and efficient power electronic devices enables precise control of motor speed, torque, and direction. These technologies have resulted in more efficient and reliable motor operation, reduced energy consumption, and enhanced motor performance in various applications.

4. Integrated Motor Systems:

Integrated motor systems combine the motor, motor controller, and associated electronics into a single unit. These integrated systems offer compact designs, simplified installation, and improved overall performance. By integrating the motor and controller, issues related to compatibility and communication between separate components are minimized. Integrated motor systems are commonly used in applications such as robotics, electric vehicles, and industrial automation.

5. IoT and Connectivity:

The integration of DC motors with Internet of Things (IoT) technologies and connectivity has opened up new possibilities for monitoring, control, and optimization of motor performance. By incorporating sensors, actuators, and connectivity features, DC motors can be remotely monitored, diagnosed, and controlled. This enables predictive maintenance, energy optimization, and real-time performance adjustments, leading to improved efficiency and reliability in various applications.

6. Advanced Motor Control Algorithms:

Advanced motor control algorithms, such as sensorless control and field-oriented control (FOC), have contributed to improved performance and efficiency of DC motors. Sensorless control techniques eliminate the need for additional sensors by leveraging motor current and voltage measurements to estimate rotor position. FOC algorithms optimize motor control by aligning the magnetic field with the rotor position, resulting in improved torque and efficiency, especially at low speeds.

These innovations and emerging technologies in DC motor design have revolutionized the capabilities and performance of DC motors. Brushless DC motors, high-efficiency materials, advanced motor control techniques, integrated motor systems, IoT connectivity, and advanced control algorithms have collectively contributed to more efficient, reliable, and versatile DC motor solutions across various industries and applications.

editor by CX 2024-05-17

China OEM 3HP~20HP electric boat motor with brushless DC motor vacuum pump connector

Product Description

Boating with EZ Outboard is Fun, Pleasant, Easy for EVERYBODY!

EZ of Use. Clean. Quiet. Light. Efficient. Safe. Reliable. Affordable

A growing number of boat owners favour electric propulsion to power their recreational boats, dinghy, kayakers, tender boats, fishing boats, catamaran, pontoons and cruisers. Electric propulsion outboard makes boating experience very fun and pleasant thanks to the ease of use, absence of engine noise, gas fumes and vibrations, and the bilge stays nice and clean with no oil or grease fouling the timber. With 90% fewer moving parts there is little that can wear out or break down, making electric motors a reliable and viable option for small boats. EZ outboards are pure electric propulsion, focused on 20HP or lower power ranges which require less battery capacity and more affordable for boat owners. Our innovative electric propulsion outboards are well designed and engineered for the highest energy efficiency, maximum safety and virtually maintenance free.

CHINAMFG Motor has been a leading manufacturer of high power BLDC motors and controllers for more than 12 years. Electric motors are core components to make electric propulsion outboards. We had started conversion of used gasoline outboards to electric version by replacing combustion engines with BLDC motors about 9 years ago. We have gained in-depth experience and knowledge about gasoline outboards from this conversion business, and learnt its pros and cons. In the end, we decided to completely re-design electric propel outboards to address the issues and weakness areas we found from existing gasoline outboards, and to best make use of full advantages of our high efficiency (>90%) and durable (>20000 hours of working life) BLDC motors. The idea is to help the environment, cut down on noise and save heaps of money in maintenance. Boats with EZ Outboard can sit all winter and won’t require winterization and oil changes, no maintenance or only minimum maintenance is required.

(E for Electric Propulsion, Z for Zero Pollution, EZ also for Ease of Use) is our new brand name for our innovative design electric propulsion outboards (international patented). Its patented gearless, brushless, shaft-less design makes it very efficient, reliable, quiet, light, compact, and cost saving. The new designs also take consideration of compatibility of installation, teleflex remote control and exchangeable propellers with conventional gasoline outboards. The BLDC motors and controllers are optimally designed for electric outboards use with motor speeds (2000rpm-2800rpm) matching to common propellers without speed reduction gears, so you can get the same boat speeds as by gasoline outboards with equivalent horse powers. EZ outboard shaft length is All-in-One size, user adjustable between long and short to cater for different boat installations, boat loads which may vary dynamically from time to time. This useful feature makes boat builders, owners and outboard dealer’s business much easier, no more confusion on shaft lengths, no more excessive stock for long and short shaft outboards! The motor controllers are sinewave technology guaranteed smoothness control, and programmable via PC or smartphones to setup speed limit, maximum current, lower voltage limit as you wish to meet your needs and local authority’s regulations, whether 9.9HP or 10HP, you can program it! Its real performance and rich features will be beyond your expectation.

We come up 2 series of pure electric outboards: One we called Sports and Commercial Series for those who want fast boat speeds as drived by gasoline outboards, the propeller speeds are between 2500-2800rpm; Another we called Leisure Series for those who need slower boat speeds, larger thrust force and less batteries required, very light in weight(15kgs – 22kgs) and quick setup (30 seconds only), the propeller speeds are between 1200-1600rpm. Both series of electric propulsion outboards are equiped with our patented brushless and gearless drive motors, direct drive without speed reduction gear from motor to propeller, highest reliability and energy efficiency guaranteed. All EZ outboards support both tiller steering control, and remote steering control via teleflex cable same way as used in gasoline outboards. Any single outboard readily caters for both control methods. You can choose either control method at the same price!

Learn to Operate It in Minutes! Smooth Control Assured.

One EZ Outboard Serves Multiple Purposes: Sporting, Cruising, Trolling

Sports Series Features: Pursuit of Speed, Sports Experience

1) Propeller speeds are comparable to conventional gasoline/diesel outboards.

2) High-power high-efficiency brushless DC drive motor (3KW-10KW) provides strong continuous thrust

3) Gearless transmission, no speed reduction mechanism, making the design more concise, quiet, durable, and energy-saving

4) Long/short shaft All-in-One, users can adjust the installation depth and angle at any time to optimize the propulsion efficiency

5) Remote/Tiller control compatible interface, users can freely choose/switch control modes

6) 3-speed selectable modes: Sports / Cruise / Eco power saving, suitable for different use scenarios, to achieve a multi-purpose

7) Internal circulation cooling system similar to the car, which improves the life of the pump and is maintenance-free. Use the car’s universal coolant to suit the local climate

8) Adopting the general-purpose gasoline engine propeller mounting interface, it is more convenient and economical to replace propeller

9) FREE smartphone meter display APPs, available in both Android and iOS versions:

10) Open support for any 48VDC battery systems, users are free to choose a local battery suppliers

11) Machine installation is common with gasoline engines, simple and maintenance-free

12) The prices are equivalent to the four-stroke gasoline engine, affordable, and truly create values for users

| EZ Outboard Key Features | |

| Electric | Zero-pollution |

| Electric Propulsion | Zero Emission |

| Economical Saving | Zero Fuel |

| Extreme High Efficiency | Zero Odor |

| Extraordinary Durable | Zero Maintenance |

| EZ to Use | |

| Easy to Setup and Operate:Power Button and Throttle | |

| Multi-Speed Modes, Programmable Controller | |

| Support Tiller or Remote Steering Control in Single Machine | |

| Adjustable Transom Lengths: Long,Medium,Short (All-in-One) | |

Ultra-Light, Incredible Thrust Force, Portable Electric Outboards

Leisure Series Features: Ultra-Light, Large Thrust Force, Power Saving

1) High thrust force, slower speed, power saving, very suitable for leisure boats.

2) There is no need of expensive large battery packs

3) Brushless, high torque drive motor (2KW-6KW) for strong continuous thrust force

4) Gearless, no speed reduction mechanism, making the mechanical design more concise, quiet, durable, and energy-saving

5) Long/short shaft All-in-One, users can adjust the installation depth and angle at any time to optimize the propulsion efficiency

6) Remote/Tiller control compatible interface, users can freely choose/switch control modes

7) 3-speed selectable modes: Sports / Cruise / Eco power saving, suitable for different use scenarios, to achieve a multi-purpose

8) FREE smartphone meter display APPs, available in both Android and iOS versions:

9) Open support for any 48VDC battery systems, users are free to choose a local battery suppliers

10) Machine installation is common with gasoline engines, simple and maintenance-free

11) The prices are equivalent to the four-stroke gasoline engine, affordable, and truly create values for users

How do I determine the capacity of the battery pack needed?

Battery is the new form of “fuel” for electric propulsion outboards, you never need to go to gasoline station to refuel your outboard anymore. You only need to recharge your batteries at home or docking place.

Once you’ve chosen an electric outboard that properly fits the weight and efficiency of your loaded boat, the next task is to size the battery bank that will store the energy to drive it. The size of the battery bank will depend on the AMP draw you plan to regularly place CHINAMFG it and the range of HangZhous you desire to travel. It is not easy to know the current draw before you try it as each boat is diffrent from others in hull shape, length, load, speed and daily operation hour you want, not like electric cars which is fixed for each car model in factory. Our expandable battery modules will make your life much easier to determine how big the battery bank you need to meet your purpose. You can just buy 1 battery module first to test boat performance with electric propel outboard and find out accurate AMP draw for your special boat setup in diffrent speed. After initial boat testing, then you can easily figure out how many such battery modules required to get the boat speed and travel duration you want. You can easily parallel link up to 4 expandable battery modules to form a larger capacity battery bank by using our Scalable Battery Hub (QuadCell, see product photo below). You can use 2 such hubs to link 8 battery modules. Each battery module is light weight for 1 person to carry around. Each module has its own battery management system (built-in BMS) and charger. We have developed 3 models of battery module for diffrent electric boats, 48V20AH, 48V30AH and 48V50AH. Their features and functions are basically same except they have different capacities. All have its built-in LED meter and support blue-tooth connection to Android smart phones. There is free downloadable APP to show battery information, like voltage, current drawn, capacity remaining, internal temerature and GPS speed of running boat.

Hold and Turn Picture below to View Product in 360 Degree, Product Name: QuadCell

We choose the most safe LiFePO4 battery type for our expanable battery modules, the materials used inside battery cell will not cause any fire or explosion. The quality of cell is very consistent and can last more than 2000 charging cycles. Its C-rating is 3 times, that means a single 48V50AH module can output 150A continuosly. That’s why you can buy just 1 or 2 battery modules first, to test the outboard motor performance and get amperage to calculate before you know the exact battery capacity you need.

For example, your trial boat testing shows you the motor current drawn from battery module is around 65A, if you need to operate your boat for 3 hours, then you need 65A*3H=195Ah battery capacity to meet your minimum requirements, this tells that you have to buy 4 sets of 48V50AH (4*50Ah=200Ah) battery modules all together.

Why we choose 48V system for outboard motor and battery pack, because it is safe for human and easy to pass local government safety regulations.

Of course, you can always buy other type of batteries from third party suppliers you can find locally, as long as its output voltage is 48V, and capacity is enough to drive the electric outboards.

Customers feedback:

Leisure Series:

Sports Series:

Accessories for Teleflex/Remote Control:

Teleflex Cabling Set, Stainless Steering Wheel, Remote Control Joystick Set

Factory Production:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Engine Position: | Outboard |

|---|---|

| Condition: | New |

| Motor: | BLDC |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the basic working principle behind a DC motor?

A DC (Direct Current) motor operates based on the fundamental principle of electromagnetic induction. It converts electrical energy into mechanical motion by utilizing the interaction between magnetic fields and current-carrying conductors. Here’s a detailed explanation of the basic working principle behind a DC motor:

1. Construction:

A DC motor consists of several key components:

- Stator: The stator is the stationary part of the motor and typically consists of permanent magnets or electromagnets that produce a fixed magnetic field.

- Rotor: The rotor is the moving part of the motor and is connected to the shaft. It contains coils or windings that carry the armature current.

- Armature: The armature is the core of the rotor that holds the armature windings. The windings are usually made of copper wire and are evenly spaced around the armature.

- Commutator: The commutator is a cylindrical ring attached to the rotor shaft. It consists of multiple segments, usually made of copper, that are insulated from each other.

- Brushes: The brushes are stationary contacts that make physical contact with the commutator segments. They are typically made of carbon or graphite and provide electrical connections to the armature windings.

2. Electromagnetic Induction:

When a current-carrying conductor is placed in a magnetic field, it experiences a force due to the interaction between the magnetic field and the current. This phenomenon is described by the right-hand rule, where the direction of the force is perpendicular to both the current direction and the magnetic field direction.

3. Motor Operation:

When a DC motor is powered, a DC voltage is applied to the armature windings through the brushes and commutator. The current flowing through the armature windings creates a magnetic field around the windings. This magnetic field interacts with the fixed magnetic field produced by the stator, resulting in a force that causes the rotor to rotate.

4. Commutation:

The commutation process is crucial for the continuous rotation of the rotor in a DC motor. As the rotor spins, the brushes make contact with different commutator segments, effectively reversing the direction of the current in the armature windings at the appropriate timing. This reversal of current flow ensures that the torque generated in the armature windings is always in the same direction, allowing for continuous rotation of the rotor.

5. Speed Control:

The speed of a DC motor can be controlled by varying the applied voltage. Reducing the voltage results in a decrease in the magnetic field strength, which in turn decreases the force acting on the armature windings. This reduction in force leads to a decrease in the motor’s speed. Conversely, increasing the voltage increases the speed of the motor. Precise speed control can be achieved by using electronic circuits to regulate the voltage supplied to the motor.

6. Advantages and Applications:

DC motors offer several advantages, including:

- High starting torque, making them suitable for applications requiring high initial force.

- Excellent speed control capabilities, allowing for precise and adjustable speed regulation.

- Relatively simple construction and ease of maintenance.

- Wide range of sizes and power ratings, making them adaptable to various applications.

DC motors find extensive use in numerous applications, such as robotics, industrial automation, electric vehicles, appliances, and more.

By understanding the basic working principle behind a DC motor, one can appreciate its functionality and explore its applications in different fields.

Are there specific types of DC motors designed for different industries or applications?

Yes, there are specific types of DC (Direct Current) motors that are designed and optimized for various industries and applications. DC motors offer a wide range of performance characteristics, allowing them to be tailored to specific requirements. Here’s a detailed explanation of the types of DC motors designed for different industries or applications:

1. Brushed DC Motors:

Brushed DC motors are commonly used in applications that require simple and cost-effective motor solutions. They are suitable for applications with lower efficiency requirements and where maintenance considerations are manageable. Some common industries and applications that use brushed DC motors include:

- Automotive: Power window mechanisms, windshield wipers, cooling fans, and seat adjustment systems.

- Consumer Electronics: Household appliances, toys, power tools, and personal care devices.

- Industrial Machinery: Conveyors, pumps, fans, and machine tools.

2. Brushless DC Motors:

Brushless DC motors are known for their higher efficiency, greater reliability, and precise control capabilities. They are widely used in industries and applications that demand higher performance and advanced control features. Some specific industries and applications that utilize brushless DC motors include:

- Automotive: Electric power steering systems, electric vehicles, hybrid vehicles, and HVAC systems.

- Aerospace and Defense: Actuators, robotics, unmanned aerial vehicles (UAVs), and missile systems.

- Medical and Laboratory Equipment: Centrifuges, pumps, robotics, and diagnostic devices.

- Industrial Automation: CNC machines, robotics, automated guided vehicles (AGVs), and precision motion control systems.

- Renewable Energy: Wind turbine generators, solar tracking systems, and energy storage systems.

3. High-Torque DC Motors:

High-torque DC motors are designed to provide substantial torque output at low speeds. They are commonly used in applications that require heavy lifting or high starting torque. Industries and applications that often utilize high-torque DC motors include:

- Material Handling: Cranes, hoists, winches, lifts, and elevators.

- Construction and Mining: Excavators, bulldozers, drilling rigs, and conveyor systems.

- Automotive: Electric vehicles, electric powertrains, and traction control systems.

- Marine and Shipbuilding: Thrusters, winches, and anchor handling systems.

4. Low-Voltage DC Motors:

Low-voltage DC motors are designed to operate at lower voltages, typically below 24 volts. They are commonly used in battery-powered applications and systems where safety or specific voltage requirements exist. Some industries and applications that utilize low-voltage DC motors include:

- Automotive: Automotive accessories, window actuators, and door locks.

- Robotics and Hobbyist Projects: DIY robots, RC vehicles, and model trains.

- Solar Power Systems: Solar tracking systems, solar panel actuators, and solar-powered water pumps.

- Home Automation: Automated blinds, curtains, and smart home devices.

These are just a few examples of the types of DC motors designed for different industries and applications. The versatility and adaptability of DC motors make them suitable for a wide range of uses, and manufacturers often offer customized motor solutions to meet specific requirements.

Are there innovations or emerging technologies in the field of DC motor design?

Yes, there have been several innovations and emerging technologies in the field of DC (Direct Current) motor design. These advancements aim to improve the performance, efficiency, reliability, and overall capabilities of DC motors. Here’s a detailed explanation of some notable innovations and emerging technologies in DC motor design:

1. Brushless DC Motors:

One significant advancement in DC motor design is the development and widespread adoption of brushless DC motors (BLDC motors). Unlike traditional DC motors that use brushes for commutation, BLDC motors employ electronic commutation through the use of permanent magnets and motor controller circuits. This eliminates the need for brushes, reducing maintenance requirements and improving overall motor efficiency and lifespan. BLDC motors offer higher torque density, smoother operation, better speed control, and improved energy efficiency compared to conventional brushed DC motors.

2. High-Efficiency Materials:

The use of high-efficiency materials in DC motor design has been an area of focus for improving motor performance. Advanced magnetic materials, such as neodymium magnets, have allowed for stronger and more compact motor designs. These materials increase the motor’s power density, enabling higher torque output and improved efficiency. Additionally, advancements in materials used for motor windings and core laminations have reduced electrical losses and improved overall motor efficiency.

3. Power Electronics and Motor Controllers:

Advancements in power electronics and motor control technologies have greatly influenced DC motor design. The development of sophisticated motor controllers and efficient power electronic devices enables precise control of motor speed, torque, and direction. These technologies have resulted in more efficient and reliable motor operation, reduced energy consumption, and enhanced motor performance in various applications.

4. Integrated Motor Systems:

Integrated motor systems combine the motor, motor controller, and associated electronics into a single unit. These integrated systems offer compact designs, simplified installation, and improved overall performance. By integrating the motor and controller, issues related to compatibility and communication between separate components are minimized. Integrated motor systems are commonly used in applications such as robotics, electric vehicles, and industrial automation.

5. IoT and Connectivity:

The integration of DC motors with Internet of Things (IoT) technologies and connectivity has opened up new possibilities for monitoring, control, and optimization of motor performance. By incorporating sensors, actuators, and connectivity features, DC motors can be remotely monitored, diagnosed, and controlled. This enables predictive maintenance, energy optimization, and real-time performance adjustments, leading to improved efficiency and reliability in various applications.

6. Advanced Motor Control Algorithms:

Advanced motor control algorithms, such as sensorless control and field-oriented control (FOC), have contributed to improved performance and efficiency of DC motors. Sensorless control techniques eliminate the need for additional sensors by leveraging motor current and voltage measurements to estimate rotor position. FOC algorithms optimize motor control by aligning the magnetic field with the rotor position, resulting in improved torque and efficiency, especially at low speeds.

These innovations and emerging technologies in DC motor design have revolutionized the capabilities and performance of DC motors. Brushless DC motors, high-efficiency materials, advanced motor control techniques, integrated motor systems, IoT connectivity, and advanced control algorithms have collectively contributed to more efficient, reliable, and versatile DC motor solutions across various industries and applications.

editor by CX 2024-05-09

China supplier 150W 24V DC Brushless Motor with 3000rpm for Grinding and Cutting Machine vacuum pump electric

Product Description

China supplier 60mm wide 3000rpm high speed bldc motor 24V 150W DC Brushless motor for Grinding and cutting machine

This link only includes the price of the motor, and does not include the driver. If you need the driver, please contact customer service to buy it separately

Get a discount

You may like

Related products

Click the picture model number

jump the product page

Our Services

Company Information

Our Certificate

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Operating Speed: | Adjust Speed |

|---|---|

| Function: | Control |

| Casing Protection: | Protection Type |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

How is the efficiency of a DC motor determined, and what factors can affect it?

In a DC (Direct Current) motor, efficiency refers to the ratio of the motor’s output power (mechanical power) to its input power (electrical power). It is a measure of how effectively the motor converts electrical energy into mechanical work. The efficiency of a DC motor can be determined by considering several factors that affect its performance. Here’s a detailed explanation of how the efficiency of a DC motor is determined and the factors that can influence it:

The efficiency of a DC motor is calculated using the following formula:

Efficiency = (Output Power / Input Power) × 100%

1. Output Power: The output power of a DC motor is the mechanical power produced at the motor’s shaft. It can be calculated using the formula:

Output Power = Torque × Angular Speed

The torque is the rotational force exerted by the motor, and the angular speed is the rate at which the motor rotates. The output power represents the useful work or mechanical energy delivered by the motor.

2. Input Power: The input power of a DC motor is the electrical power supplied to the motor. It can be calculated using the formula:

Input Power = Voltage × Current

The voltage is the electrical potential difference applied to the motor, and the current is the amount of electrical current flowing through the motor. The input power represents the electrical energy consumed by the motor.

Once the output power and input power are determined, the efficiency can be calculated using the formula mentioned earlier.

Several factors can influence the efficiency of a DC motor:

1. Copper Losses:

Copper losses occur due to the resistance of the copper windings in the motor. These losses result in the conversion of electrical energy into heat. Higher resistance or increased current flow leads to greater copper losses and reduces the efficiency of the motor. Using thicker wire for the windings and minimizing resistance can help reduce copper losses.

2. Iron Losses:

Iron losses occur due to magnetic hysteresis and eddy currents in the motor’s iron core. These losses result in the conversion of electrical energy into heat. Using high-quality laminated iron cores and minimizing magnetic flux variations can help reduce iron losses and improve efficiency.

3. Friction and Windage Losses:

Friction and windage losses occur due to mechanical friction between moving parts and air resistance. These losses result in the conversion of mechanical energy into heat. Proper lubrication, efficient bearing systems, and aerodynamically optimized designs can help minimize friction and windage losses.

4. Brush and Commutator Losses:

In brushed DC motors, brush and commutator losses occur due to the friction and electrical resistance at the brush-commutator interface. These losses result in the conversion of electrical energy into heat. Using high-quality brushes and commutators, reducing brush voltage drop, and minimizing the number of commutator segments can help reduce these losses.

5. Magnetic Field Design:

The design of the magnetic field in the motor significantly affects its efficiency. Optimizing the magnetic field for the specific application, such as selecting appropriate magnet materials or designing efficient electromagnets, can improve the motor’s efficiency.

6. Motor Load:

The load on the motor, including the torque and speed requirements, can impact its efficiency. Operating the motor close to its optimal load conditions or utilizing speed control techniques, such as pulse width modulation (PWM), can help improve efficiency by reducing unnecessary power consumption.

7. Motor Size and Construction:

The size and construction of the motor can influence its efficiency. Properly sizing the motor for the intended application and optimizing the design for reduced losses, improved cooling, and efficient heat dissipation can enhance overall efficiency.

It’s important to note that the efficiency of a DC motor is typically highest at or near its rated load conditions. Deviating significantly from the rated load can result in reduced efficiency.

In summary, the efficiency of a DC motor is determined by comparing the output power to the input power. Factors such as copper losses, iron losses, friction and windage losses, brush and commutator losses, magnetic field design, motor load, and motor size and construction can all influence the efficiency of a DC motor. By considering and optimizing these factors, the overall efficiency of the motor can be improved.

Can DC motors be used in robotics, and if so, what are some notable applications?

Yes, DC (Direct Current) motors can be used in robotics, and they are widely employed in various robotic applications. DC motors offer several advantages that make them suitable for robotic systems, including their controllability, compact size, and versatility. Here’s a detailed explanation of how DC motors are used in robotics and some notable applications:

DC Motors in Robotics:

DC motors are commonly used in robotics due to their ability to provide precise speed control and torque output. They can be easily controlled by adjusting the voltage applied to the motor, allowing for accurate and responsive motion control in robotic systems. Additionally, DC motors can be designed in compact sizes, making them suitable for applications with limited space and weight constraints.

There are two main types of DC motors used in robotics:

- DC Brushed Motors: These motors have a commutator and carbon brushes that provide the electrical connection to the rotating armature. They are relatively simple in design and cost-effective. However, they may require maintenance due to brush wear.

- DC Brushless Motors: These motors use electronic commutation instead of brushes, resulting in improved reliability and reduced maintenance requirements. They are often more efficient and offer higher power density compared to brushed motors.

Notable Applications of DC Motors in Robotics:

DC motors find applications in various robotic systems across different industries. Here are some notable examples:

1. Robotic Manipulators: DC motors are commonly used in robotic arms and manipulators to control the movement of joints and end-effectors. They provide precise control over position, speed, and torque, allowing robots to perform tasks such as pick-and-place operations, assembly, and material handling in industrial automation, manufacturing, and logistics.

2. Mobile Robots: DC motors are extensively utilized in mobile robots, including autonomous vehicles, drones, and rovers. They power the wheels or propellers, enabling the robot to navigate and move in different environments. DC motors with high torque output are particularly useful for off-road or rugged terrain applications.

3. Humanoid Robots: DC motors play a critical role in humanoid robots, which aim to replicate human-like movements and capabilities. They are employed in various joints, including those of the head, arms, legs, and hands, allowing humanoid robots to perform complex movements and tasks such as walking, grasping objects, and facial expressions.

4. Robotic Exoskeletons: DC motors are used in robotic exoskeletons, which are wearable devices designed to enhance human strength and mobility. They provide the necessary actuation and power for assisting or augmenting human movements, such as walking, lifting heavy objects, and rehabilitation purposes.

5. Educational Robotics: DC motors are popular in educational robotics platforms and kits, including those used in schools, universities, and hobbyist projects. They provide a cost-effective and accessible way for students and enthusiasts to learn about robotics, programming, and control systems.

6. Precision Robotics: DC motors with high-precision control are employed in applications that require precise positioning and motion control, such as robotic surgery systems, laboratory automation, and 3D printing. The ability of DC motors to achieve accurate and repeatable movements makes them suitable for tasks that demand high levels of precision.

These are just a few examples of how DC motors are used in robotics. The flexibility, controllability, and compactness of DC motors make them a popular choice in a wide range of robotic applications, contributing to the advancement of automation, exploration, healthcare, and other industries.

editor by CX 2024-05-08

China high quality Swimming Pool Low Noise 3 Phase Motor 12V 24V DC Brushless Pum vacuum pump adapter

Product Description

Why choose CHINAMFG Factory ?

♦ CHINAMFG is the only double certified enterprise by German TUV IATF16949 & ISO9001 in the pump industry

♦ 16 years of industry experience.Independent research and development, national high-tech enterprise, multiple domestic and foreign invention patents

♦ Annual production capacity of 3,008,000 pieces

♦ 4 laboratories that meeting the CNAS certification standard

♦ 80% of the products are exported to high-end market in Europe and America

Remarks:

– We are High-end Brushless DC pumps Manufacturer. Can provide customized services

– If you are interested in our products, pls feel free to contact us

Customer Reviews

WRAS approved Big flow high pressure Quiet Pumped Electric Shower pump

Φ Advanced magnetic driving technology for static-seal,without any leakage forever

Φ Heavy duty work,can sustain continuous 24hours work

Φ High efficiency ECM brushless DC motor with long lifetime 25,000hours

Φ 3-phase motor for lower power consumption and lower fever

Φ Durable permanent magnetic rotor/impeller and fine ceramic shaft

Φ Specializing closed-type impeller for lower water loss bring higher efficiency

Φ High temperature materials for liquid temperature ≥100°C

Φ Low or no maintenance

Φ Food grade materials

Φ Imported Japan XYRON PPE material, certificated by WRAS .

Specification

| Model | Product Code | Max Water Flow (L/Min) | Rated Voltage(DC) | Rated Current (A) | Max Water Head(M) | Rated Power(W) | Speed (RPM) |

|

| C01 | TL-C01-A12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | |

| TL-C01-B12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-C12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-D12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-A12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-B12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-C12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-D12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-A24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-B24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-C24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-D24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5530 | ||

| TL-C01-A24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-B24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-C24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-D24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

|

(customized functions) 1.PWM, 0~5V speed control, |

||||||||

| Motor | High performance 3-phase motor | ||||||

| 12V Highest operating voltage | 18V | ||||||

| 12V Starting voltage | 6V | ||||||

| 24V Highest operating voltage | 28V | ||||||

| 24V Starting voltage | 12V | ||||||

| Working rated | Continuous | ||||||

| Noise | ≤45dB(A) from 1M Distance | ||||||

| Coil Insulation class | Class F | ||||||

| Media | Water, antifreeze,other | ||||||

| Power Supply | DC power supply, battery, solar powered | ||||||

| Remarks | Can’t dry-running, not Self-priming | ||||||

| The technical parameters above is only for your reference, for more details , please feel free to contact us. | |||||||

1. Liquid transfer general purpose pumping 2. Hot water circulating system

3. Electronics Cooling Water Circulation Chiller Systems

4. Liquid filling and transfer in food, beverage processing, vending machines

5. Instant electric water heater, electric shower.

6. Circulating systems for homes, RV’s and boats

7. Cleaning equipment, purification and water treatment.

8. Irrigation solar pump, swimming pool circulation 9. Electric cars: radiators, heaters

Get more information, Please Send Message

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Max.Head: | 8m 11m |

|---|---|

| Max.Capacity: | 18L 20L 22L |

| Driving Type: | Magnetic |

| Material: | Imported PPE |

| Structure: | Single-stage Pump |

| Assembly: | Booster Pump |

| Samples: |

US$ 28/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is a DC motor, and how does it differ from other types of electric motors?

A DC (Direct Current) motor is an electric motor that converts electrical energy into mechanical motion. It operates based on the principle of electromagnetic induction and the interaction between current-carrying conductors and magnetic fields. DC motors are widely used in various applications due to their simplicity, controllability, and versatility. Here’s a detailed explanation of what a DC motor is and how it differs from other types of electric motors:

1. Basic Operation:

In a DC motor, electrical energy is supplied to the motor’s armature through a DC power source, typically a battery or a rectified power supply. The armature consists of multiple coils or windings that are evenly spaced around the motor’s rotor. The rotor is a cylindrical core with a shaft that rotates when the motor is energized. When current flows through the armature windings, it creates a magnetic field that interacts with the fixed magnetic field produced by the motor’s stator. This interaction generates a torque, causing the rotor to rotate.

2. Commutation:

DC motors employ a commutator and brushes for the conversion of electrical energy and the rotation of the rotor. The commutator consists of a segmented cylindrical ring attached to the rotor shaft, and the brushes are stationary conductive contacts that make contact with the commutator segments. As the rotor spins, the brushes maintain contact with the commutator segments, periodically reversing the direction of the current flow in the armature windings. This reversal of current flow in the armature windings ensures continuous rotation of the rotor in the same direction.

3. Types of DC Motors:

DC motors can be classified into different types based on their construction and the method of field excitation. The two main types are:

- Brushed DC Motors: Brushed DC motors have a mechanical commutator and brushes to switch the current direction in the armature windings. These motors are relatively simple, cost-effective, and offer good torque characteristics. However, the commutator and brushes require regular maintenance and can generate electrical noise and brush wear debris.

- Brushless DC Motors (BLDC): Brushless DC motors, also known as electronically commutated motors (ECMs), use electronic circuits and sensors to control the current flow in the motor windings. They eliminate the need for brushes and commutators, resulting in reduced maintenance and improved reliability. BLDC motors offer higher efficiency, smoother operation, and better speed control compared to brushed DC motors.

4. Speed Control:

DC motors provide excellent speed control capabilities. By adjusting the voltage applied to the motor, the speed of the DC motor can be regulated. Lowering the voltage reduces the motor’s speed, while increasing the voltage increases the speed. This feature makes DC motors suitable for applications that require precise speed control, such as robotics, conveyor systems, and electric vehicles.

5. Advantages and Disadvantages:

DC motors have several advantages, including:

- Simple construction and easy maintenance (for brushed DC motors).

- High starting torque.

- Precise speed control.

- Good controllability over a wide range of loads.

However, DC motors also have some limitations, such as:

- Brushed DC motors require periodic maintenance and have limited brush life.

- Brushed DC motors can generate electrical noise.

- Brushless DC motors are often more expensive compared to brushed DC motors.

6. Differences from Other Electric Motors:

DC motors differ from other types of electric motors, such as AC (Alternating Current) motors, in several ways:

- Power Source: DC motors require a DC power source, while AC motors operate from an AC power supply.

- Speed Control: DC motors offer precise speed control by adjusting the applied voltage, whereas AC motors typically rely on frequency control for speed regulation.

- Construction: DC motors use a commutator and brushes (in brushed DC motors) or electronic commutation (in brushless DC motors), while AC motors do not require commutation.

- Starting Torque: DC motors typically provide higher starting torque compared to AC motors.

Overall, DC motors are versatile and widely used in various applications due to their controllability, speed regulation capabilities, and simplicity. The advancements inpower electronics and motor control technologies have further enhanced the performance and efficiency of DC motors, making them a popular choice in many industries.

How is the efficiency of a DC motor determined, and what factors can affect it?

In a DC (Direct Current) motor, efficiency refers to the ratio of the motor’s output power (mechanical power) to its input power (electrical power). It is a measure of how effectively the motor converts electrical energy into mechanical work. The efficiency of a DC motor can be determined by considering several factors that affect its performance. Here’s a detailed explanation of how the efficiency of a DC motor is determined and the factors that can influence it:

The efficiency of a DC motor is calculated using the following formula:

Efficiency = (Output Power / Input Power) × 100%

1. Output Power: The output power of a DC motor is the mechanical power produced at the motor’s shaft. It can be calculated using the formula:

Output Power = Torque × Angular Speed

The torque is the rotational force exerted by the motor, and the angular speed is the rate at which the motor rotates. The output power represents the useful work or mechanical energy delivered by the motor.

2. Input Power: The input power of a DC motor is the electrical power supplied to the motor. It can be calculated using the formula:

Input Power = Voltage × Current

The voltage is the electrical potential difference applied to the motor, and the current is the amount of electrical current flowing through the motor. The input power represents the electrical energy consumed by the motor.

Once the output power and input power are determined, the efficiency can be calculated using the formula mentioned earlier.

Several factors can influence the efficiency of a DC motor:

1. Copper Losses:

Copper losses occur due to the resistance of the copper windings in the motor. These losses result in the conversion of electrical energy into heat. Higher resistance or increased current flow leads to greater copper losses and reduces the efficiency of the motor. Using thicker wire for the windings and minimizing resistance can help reduce copper losses.

2. Iron Losses:

Iron losses occur due to magnetic hysteresis and eddy currents in the motor’s iron core. These losses result in the conversion of electrical energy into heat. Using high-quality laminated iron cores and minimizing magnetic flux variations can help reduce iron losses and improve efficiency.

3. Friction and Windage Losses:

Friction and windage losses occur due to mechanical friction between moving parts and air resistance. These losses result in the conversion of mechanical energy into heat. Proper lubrication, efficient bearing systems, and aerodynamically optimized designs can help minimize friction and windage losses.

4. Brush and Commutator Losses:

In brushed DC motors, brush and commutator losses occur due to the friction and electrical resistance at the brush-commutator interface. These losses result in the conversion of electrical energy into heat. Using high-quality brushes and commutators, reducing brush voltage drop, and minimizing the number of commutator segments can help reduce these losses.

5. Magnetic Field Design:

The design of the magnetic field in the motor significantly affects its efficiency. Optimizing the magnetic field for the specific application, such as selecting appropriate magnet materials or designing efficient electromagnets, can improve the motor’s efficiency.

6. Motor Load:

The load on the motor, including the torque and speed requirements, can impact its efficiency. Operating the motor close to its optimal load conditions or utilizing speed control techniques, such as pulse width modulation (PWM), can help improve efficiency by reducing unnecessary power consumption.

7. Motor Size and Construction:

The size and construction of the motor can influence its efficiency. Properly sizing the motor for the intended application and optimizing the design for reduced losses, improved cooling, and efficient heat dissipation can enhance overall efficiency.

It’s important to note that the efficiency of a DC motor is typically highest at or near its rated load conditions. Deviating significantly from the rated load can result in reduced efficiency.

In summary, the efficiency of a DC motor is determined by comparing the output power to the input power. Factors such as copper losses, iron losses, friction and windage losses, brush and commutator losses, magnetic field design, motor load, and motor size and construction can all influence the efficiency of a DC motor. By considering and optimizing these factors, the overall efficiency of the motor can be improved.

Where can individuals find reliable resources for learning more about DC motors and their applications?

Individuals seeking reliable resources to learn more about DC (Direct Current) motors and their applications can explore various sources that provide comprehensive and accurate information. Here’s a detailed explanation of where individuals can find reliable resources for learning about DC motors:

1. Manufacturer Websites:

Many DC motor manufacturers have dedicated sections on their websites that provide detailed information about their products, including specifications, application notes, technical guides, and whitepapers. These resources offer valuable insights into the design, operation, and application considerations of DC motors. Examples of reputable DC motor manufacturers include Baldor, Maxon Motor, and Faulhaber.

2. Industry Associations and Organizations:

Industry associations and organizations related to electrical engineering, automation, and motor technology can be excellent sources of reliable information. Examples include the Institute of Electrical and Electronics Engineers (IEEE) and the American Society of Mechanical Engineers (ASME). These associations often provide access to technical publications, research papers, conferences, and educational resources related to DC motors and their applications.

3. Technical Books and Publications:

Technical books and publications authored by experts in the field of electrical engineering and motor technology can provide in-depth knowledge about DC motors. Books such as “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and “Practical Electric Motor Handbook” by Irving Gottlieb are widely regarded as reliable resources for learning about DC motors and their applications.

4. Online Educational Platforms:

Online educational platforms offer a wealth of resources for learning about DC motors. Websites like Coursera, Udemy, and Khan Academy provide online courses, tutorials, and video lectures on electrical engineering, motor theory, and applications. These platforms often have courses specifically dedicated to DC motors, covering topics such as motor principles, control techniques, and practical applications.

5. Research Papers and Scientific Journals:

Research papers published in scientific journals and conference proceedings can provide detailed insights into the latest advancements and research findings related to DC motors. Platforms like IEEE Xplore, ScienceDirect, and Google Scholar can be used to search for scholarly articles on DC motors. These papers are authored by researchers and experts in the field and provide reliable and up-to-date information on various aspects of DC motor technology.

6. Online Forums and Communities:

Online forums and communities focused on electrical engineering, motor technology, and DIY projects can be valuable resources for learning about DC motors. Platforms like Reddit, Stack Exchange (Electrical Engineering section), and specialized motor forums provide opportunities to ask questions, engage in discussions, and learn from experienced individuals in the field. However, it’s important to verify information obtained from online forums as they may contain a mix of opinions and varying levels of expertise.

When accessing these resources, it’s essential to critically evaluate the information and cross-reference it with multiple sources to ensure accuracy and reliability. By utilizing a combination of manufacturer websites, industry associations, technical books, online educational platforms, research papers, and online communities, individuals can gain a comprehensive understanding of DC motors and their applications.

editor by CX 2024-05-07

China factory 10 Inch 1500W All-in-One Brushless DC Direct Drive Electric Motorcycle Scooter Hub Motor Black Double IP67 Scooter vacuum pump belt

Product Description

Used in scooter and motorcycle with high power

giving excellent balance capacity,comfortable,smooth and durable in use.

| Working voltage | DC48V-72V |

| No load speed | 490±10rpm |

| Rated power | 1500-2500W |

| Efficiency | ≥85% |

| Maximum torque | >72Nm |

| Maximum speed | 35km/h-50km/h |

| Motor on gear | 170mm |

| Brake type | Drum/Disc brake |

| Colour | Matt black/silver |

| Adaptive tire | English 3.0-10 3.5-10 |

| Metric 110 / 100-10 110 / 90-10 | |

| 90/90-10 100/90-10 |

1. Q: Can I get samples before my formal order?

A: Yes, special sample services are available. And the sample cost can be relived once the formal order comes.

2. Q: How do you control the quality?

A: 1. Provide sample test report confirmation; 2. Seal sample confirmation. 3. Shoot production videos during the production process; 4. Send out test reports and test videos when the products are off-line; 5. Use foam cartons and woven bags for packaging, and the perfect packaging method ensures that the products are not damaged during transportation.

3. Q: Can I get a customize service?

A: Yes, ODM OEM services are available. (Appearance color, decal, power, etc. can be customized if the quantity can be above 50sets)

4. Q: What is the warranty time of your products?

A:The motor and controller are guaranteed for 18 months.

5. Q: How about payment terms and price terms?

A: Payment Terms: EXW,FOB,CNF/CFR,CIF,L/C, etc. Price Terms: Sample list 100%;Regular order 100% TT or 100% L/C or 30%TT,70%L/C.The specific payment method can be negotiated.

6. Q: What’s the approximate lead time?

A: After the advanced payment confirmed, normally 5 days for stock products,15 days for conventional models , and 30 days for special models. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Charge |

|---|---|

| Warranty: | 12 Mouths |

| Brake System: | Drum Brake/Disc Brake |

| Speed: | 40-60km/H |

| Supply Voltage: | DC48V |

| Rated Power: | 1500-2500W |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the key differences between brushed and brushless DC motors?

Brushed and brushless DC motors are two distinct types of motors that differ in their construction, operation, and performance characteristics. Here’s a detailed explanation of the key differences between brushed and brushless DC motors:

1. Construction:

Brushed DC Motors: Brushed DC motors have a relatively simple construction. They consist of a rotor with armature windings and a commutator, and a stator with permanent magnets or electromagnets. The commutator and brushes make physical contact to provide electrical connections to the armature windings.

Brushless DC Motors: Brushless DC motors have a more complex construction. They typically consist of a stationary stator with permanent magnets or electromagnets and a rotor with multiple coils or windings. The rotor does not have a commutator or brushes.

2. Commutation:

Brushed DC Motors: In brushed DC motors, the commutator and brushes are responsible for the commutation process. The brushes make contact with different segments of the commutator, reversing the direction of the current through the armature windings as the rotor rotates. This switching of the current direction generates the necessary torque for motor rotation.

Brushless DC Motors: Brushless DC motors use electronic commutation instead of mechanical commutation. The commutation process is managed by an external electronic controller or driver. The controller determines the timing and sequence of energizing the stator windings based on the rotor position, allowing for precise control of motor operation.

3. Efficiency:

Brushed DC Motors: Brushed DC motors tend to have lower efficiency compared to brushless DC motors. This is primarily due to the energy losses associated with the brushes and commutation process. The friction and wear between the brushes and commutator result in additional power dissipation and reduce overall motor efficiency.

Brushless DC Motors: Brushless DC motors are known for their higher efficiency. Since they eliminate the use of brushes and commutators, there are fewer energy losses and lower frictional losses. The electronic commutation system allows for precise control of the motor’s operation, maximizing efficiency and reducing power consumption.

4. Maintenance:

Brushed DC Motors: Brushed DC motors require regular maintenance due to the wear and tear of the brushes and commutator. The brushes need periodic replacement, and the commutator requires cleaning to maintain proper electrical contact. The maintenance requirements contribute to additional costs and downtime for brushed DC motors.

Brushless DC Motors: Brushless DC motors have a relatively maintenance-free operation. As they do not have brushes or commutators, there is no need for brush replacement or commutator cleaning. This results in reduced maintenance costs and increased reliability of brushless DC motors.

5. Speed Control:

Brushed DC Motors: Brushed DC motors offer simpler speed control options. The speed can be controlled by adjusting the applied voltage or by varying the resistance in the armature circuit. This allows for relatively straightforward speed regulation.

Brushless DC Motors: Brushless DC motors provide more advanced and precise speed control capabilities. The speed can be controlled through the electronic commutation system by adjusting the timing and sequence of the stator windings’ energization. This allows for precise control of the motor’s speed and acceleration.

These key differences between brushed and brushless DC motors make each type suitable for different applications depending on factors such as efficiency requirements, maintenance considerations, and control complexity.

Are there specific types of DC motors designed for different industries or applications?

Yes, there are specific types of DC (Direct Current) motors that are designed and optimized for various industries and applications. DC motors offer a wide range of performance characteristics, allowing them to be tailored to specific requirements. Here’s a detailed explanation of the types of DC motors designed for different industries or applications:

1. Brushed DC Motors:

Brushed DC motors are commonly used in applications that require simple and cost-effective motor solutions. They are suitable for applications with lower efficiency requirements and where maintenance considerations are manageable. Some common industries and applications that use brushed DC motors include:

- Automotive: Power window mechanisms, windshield wipers, cooling fans, and seat adjustment systems.

- Consumer Electronics: Household appliances, toys, power tools, and personal care devices.

- Industrial Machinery: Conveyors, pumps, fans, and machine tools.

2. Brushless DC Motors:

Brushless DC motors are known for their higher efficiency, greater reliability, and precise control capabilities. They are widely used in industries and applications that demand higher performance and advanced control features. Some specific industries and applications that utilize brushless DC motors include:

- Automotive: Electric power steering systems, electric vehicles, hybrid vehicles, and HVAC systems.

- Aerospace and Defense: Actuators, robotics, unmanned aerial vehicles (UAVs), and missile systems.

- Medical and Laboratory Equipment: Centrifuges, pumps, robotics, and diagnostic devices.

- Industrial Automation: CNC machines, robotics, automated guided vehicles (AGVs), and precision motion control systems.

- Renewable Energy: Wind turbine generators, solar tracking systems, and energy storage systems.

3. High-Torque DC Motors:

High-torque DC motors are designed to provide substantial torque output at low speeds. They are commonly used in applications that require heavy lifting or high starting torque. Industries and applications that often utilize high-torque DC motors include: