Product Description

Why choose CHINAMFG Factory ?

♦ CHINAMFG is the only double certified enterprise by German TUV IATF16949 & ISO9001 in the pump industry

♦ 16 years of industry experience.Independent research and development, national high-tech enterprise, multiple domestic and foreign invention patents

♦ Annual production capacity of 3,008,000 pieces

♦ 4 laboratories that meeting the CNAS certification standard

♦ 80% of the products are exported to high-end market in Europe and America

Remarks:

– We are High-end Brushless DC pumps Manufacturer. Can provide customized services

– If you are interested in our products, pls feel free to contact us

Customer Reviews

WRAS approved Big flow high pressure Quiet Pumped Electric Shower pump

Φ Advanced magnetic driving technology for static-seal,without any leakage forever

Φ Heavy duty work,can sustain continuous 24hours work

Φ High efficiency ECM brushless DC motor with long lifetime 25,000hours

Φ 3-phase motor for lower power consumption and lower fever

Φ Durable permanent magnetic rotor/impeller and fine ceramic shaft

Φ Specializing closed-type impeller for lower water loss bring higher efficiency

Φ High temperature materials for liquid temperature ≥100°C

Φ Low or no maintenance

Φ Food grade materials

Φ Imported Japan XYRON PPE material, certificated by WRAS .

Specification

| Model | Product Code | Max Water Flow (L/Min) | Rated Voltage(DC) | Rated Current (A) | Max Water Head(M) | Rated Power(W) | Speed (RPM) |

|

| C01 | TL-C01-A12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | |

| TL-C01-B12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-C12-1706 | 17 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-D12-1606 | 16 | 12VDC | 2.0 | 6 | 24 | 4950 | ||

| TL-C01-A12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-B12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-C12-2008 | 20 | 12VDC | 2.8 | 8 | 33.6 | 5750 | ||

| TL-C01-D12-1908 | 19 | 12VDC | 3 | 8 | 36 | 5750 | ||

| TL-C01-A24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-B24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-C24-1908 | 19 | 24VDC | 1.33 | 8 | 31.92 | 5750 | ||

| TL-C01-D24-1808 | 18 | 24VDC | 1.33 | 8 | 31.92 | 5530 | ||

| TL-C01-A24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-B24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-C24-2411 | 24 | 24VDC | 2 | 11 | 48 | 6400 | ||

| TL-C01-D24-2211 | 22 | 24VDC | 2 | 11 | 48 | 6400 | ||

|

(customized functions) 1.PWM, 0~5V speed control, |

||||||||

| Motor | High performance 3-phase motor | ||||||

| 12V Highest operating voltage | 18V | ||||||

| 12V Starting voltage | 6V | ||||||

| 24V Highest operating voltage | 28V | ||||||

| 24V Starting voltage | 12V | ||||||

| Working rated | Continuous | ||||||

| Noise | ≤45dB(A) from 1M Distance | ||||||

| Coil Insulation class | Class F | ||||||

| Media | Water, antifreeze,other | ||||||

| Power Supply | DC power supply, battery, solar powered | ||||||

| Remarks | Can’t dry-running, not Self-priming | ||||||

| The technical parameters above is only for your reference, for more details , please feel free to contact us. | |||||||

1. Liquid transfer general purpose pumping 2. Hot water circulating system

3. Electronics Cooling Water Circulation Chiller Systems

4. Liquid filling and transfer in food, beverage processing, vending machines

5. Instant electric water heater, electric shower.

6. Circulating systems for homes, RV’s and boats

7. Cleaning equipment, purification and water treatment.

8. Irrigation solar pump, swimming pool circulation 9. Electric cars: radiators, heaters

Get more information, Please Send Message

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Max.Head: | 8m 11m |

|---|---|

| Max.Capacity: | 18L 20L 22L |

| Driving Type: | Magnetic |

| Material: | Imported PPE |

| Structure: | Single-stage Pump |

| Assembly: | Booster Pump |

| Samples: |

US$ 28/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

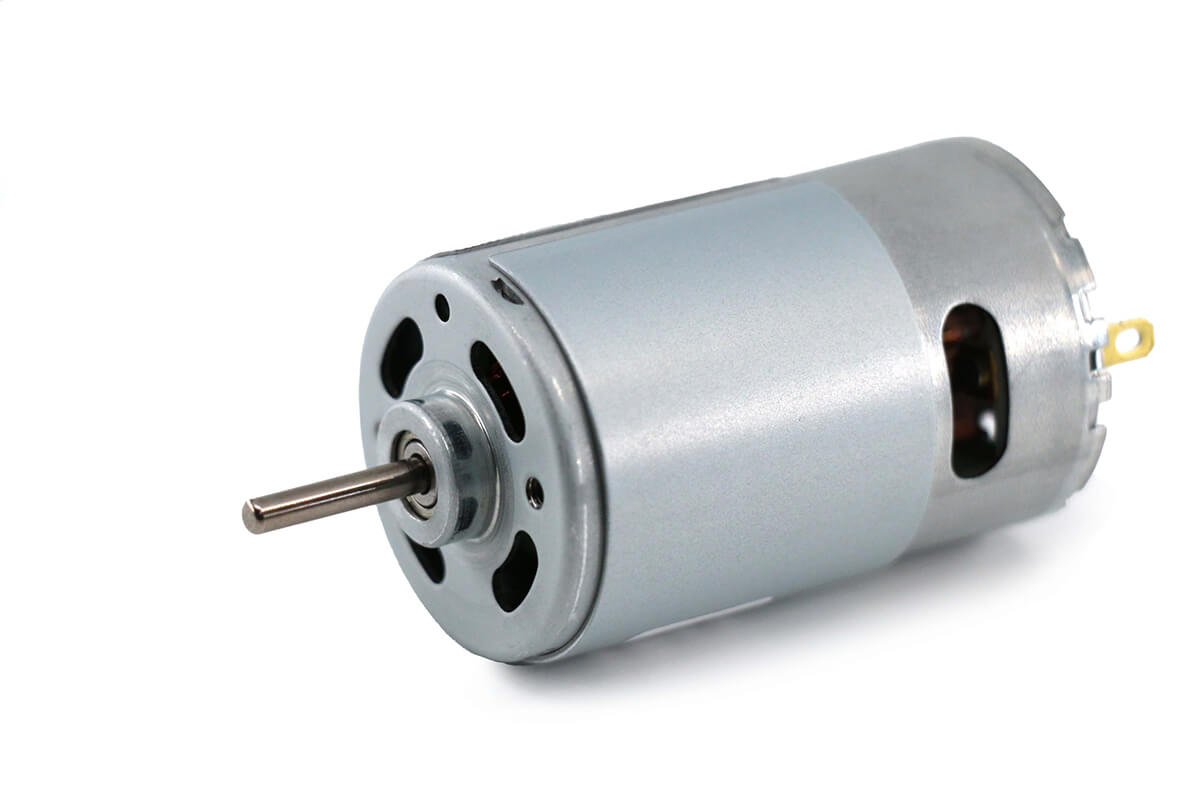

What is a DC motor, and how does it differ from other types of electric motors?

A DC (Direct Current) motor is an electric motor that converts electrical energy into mechanical motion. It operates based on the principle of electromagnetic induction and the interaction between current-carrying conductors and magnetic fields. DC motors are widely used in various applications due to their simplicity, controllability, and versatility. Here’s a detailed explanation of what a DC motor is and how it differs from other types of electric motors:

1. Basic Operation:

In a DC motor, electrical energy is supplied to the motor’s armature through a DC power source, typically a battery or a rectified power supply. The armature consists of multiple coils or windings that are evenly spaced around the motor’s rotor. The rotor is a cylindrical core with a shaft that rotates when the motor is energized. When current flows through the armature windings, it creates a magnetic field that interacts with the fixed magnetic field produced by the motor’s stator. This interaction generates a torque, causing the rotor to rotate.

2. Commutation:

DC motors employ a commutator and brushes for the conversion of electrical energy and the rotation of the rotor. The commutator consists of a segmented cylindrical ring attached to the rotor shaft, and the brushes are stationary conductive contacts that make contact with the commutator segments. As the rotor spins, the brushes maintain contact with the commutator segments, periodically reversing the direction of the current flow in the armature windings. This reversal of current flow in the armature windings ensures continuous rotation of the rotor in the same direction.

3. Types of DC Motors:

DC motors can be classified into different types based on their construction and the method of field excitation. The two main types are:

- Brushed DC Motors: Brushed DC motors have a mechanical commutator and brushes to switch the current direction in the armature windings. These motors are relatively simple, cost-effective, and offer good torque characteristics. However, the commutator and brushes require regular maintenance and can generate electrical noise and brush wear debris.

- Brushless DC Motors (BLDC): Brushless DC motors, also known as electronically commutated motors (ECMs), use electronic circuits and sensors to control the current flow in the motor windings. They eliminate the need for brushes and commutators, resulting in reduced maintenance and improved reliability. BLDC motors offer higher efficiency, smoother operation, and better speed control compared to brushed DC motors.

4. Speed Control:

DC motors provide excellent speed control capabilities. By adjusting the voltage applied to the motor, the speed of the DC motor can be regulated. Lowering the voltage reduces the motor’s speed, while increasing the voltage increases the speed. This feature makes DC motors suitable for applications that require precise speed control, such as robotics, conveyor systems, and electric vehicles.

5. Advantages and Disadvantages:

DC motors have several advantages, including:

- Simple construction and easy maintenance (for brushed DC motors).

- High starting torque.

- Precise speed control.

- Good controllability over a wide range of loads.

However, DC motors also have some limitations, such as:

- Brushed DC motors require periodic maintenance and have limited brush life.

- Brushed DC motors can generate electrical noise.

- Brushless DC motors are often more expensive compared to brushed DC motors.

6. Differences from Other Electric Motors:

DC motors differ from other types of electric motors, such as AC (Alternating Current) motors, in several ways:

- Power Source: DC motors require a DC power source, while AC motors operate from an AC power supply.

- Speed Control: DC motors offer precise speed control by adjusting the applied voltage, whereas AC motors typically rely on frequency control for speed regulation.

- Construction: DC motors use a commutator and brushes (in brushed DC motors) or electronic commutation (in brushless DC motors), while AC motors do not require commutation.

- Starting Torque: DC motors typically provide higher starting torque compared to AC motors.

Overall, DC motors are versatile and widely used in various applications due to their controllability, speed regulation capabilities, and simplicity. The advancements inpower electronics and motor control technologies have further enhanced the performance and efficiency of DC motors, making them a popular choice in many industries.

How is the efficiency of a DC motor determined, and what factors can affect it?

In a DC (Direct Current) motor, efficiency refers to the ratio of the motor’s output power (mechanical power) to its input power (electrical power). It is a measure of how effectively the motor converts electrical energy into mechanical work. The efficiency of a DC motor can be determined by considering several factors that affect its performance. Here’s a detailed explanation of how the efficiency of a DC motor is determined and the factors that can influence it:

The efficiency of a DC motor is calculated using the following formula:

Efficiency = (Output Power / Input Power) × 100%

1. Output Power: The output power of a DC motor is the mechanical power produced at the motor’s shaft. It can be calculated using the formula:

Output Power = Torque × Angular Speed

The torque is the rotational force exerted by the motor, and the angular speed is the rate at which the motor rotates. The output power represents the useful work or mechanical energy delivered by the motor.

2. Input Power: The input power of a DC motor is the electrical power supplied to the motor. It can be calculated using the formula:

Input Power = Voltage × Current

The voltage is the electrical potential difference applied to the motor, and the current is the amount of electrical current flowing through the motor. The input power represents the electrical energy consumed by the motor.

Once the output power and input power are determined, the efficiency can be calculated using the formula mentioned earlier.

Several factors can influence the efficiency of a DC motor:

1. Copper Losses:

Copper losses occur due to the resistance of the copper windings in the motor. These losses result in the conversion of electrical energy into heat. Higher resistance or increased current flow leads to greater copper losses and reduces the efficiency of the motor. Using thicker wire for the windings and minimizing resistance can help reduce copper losses.

2. Iron Losses:

Iron losses occur due to magnetic hysteresis and eddy currents in the motor’s iron core. These losses result in the conversion of electrical energy into heat. Using high-quality laminated iron cores and minimizing magnetic flux variations can help reduce iron losses and improve efficiency.

3. Friction and Windage Losses:

Friction and windage losses occur due to mechanical friction between moving parts and air resistance. These losses result in the conversion of mechanical energy into heat. Proper lubrication, efficient bearing systems, and aerodynamically optimized designs can help minimize friction and windage losses.

4. Brush and Commutator Losses:

In brushed DC motors, brush and commutator losses occur due to the friction and electrical resistance at the brush-commutator interface. These losses result in the conversion of electrical energy into heat. Using high-quality brushes and commutators, reducing brush voltage drop, and minimizing the number of commutator segments can help reduce these losses.

5. Magnetic Field Design:

The design of the magnetic field in the motor significantly affects its efficiency. Optimizing the magnetic field for the specific application, such as selecting appropriate magnet materials or designing efficient electromagnets, can improve the motor’s efficiency.

6. Motor Load:

The load on the motor, including the torque and speed requirements, can impact its efficiency. Operating the motor close to its optimal load conditions or utilizing speed control techniques, such as pulse width modulation (PWM), can help improve efficiency by reducing unnecessary power consumption.

7. Motor Size and Construction:

The size and construction of the motor can influence its efficiency. Properly sizing the motor for the intended application and optimizing the design for reduced losses, improved cooling, and efficient heat dissipation can enhance overall efficiency.

It’s important to note that the efficiency of a DC motor is typically highest at or near its rated load conditions. Deviating significantly from the rated load can result in reduced efficiency.

In summary, the efficiency of a DC motor is determined by comparing the output power to the input power. Factors such as copper losses, iron losses, friction and windage losses, brush and commutator losses, magnetic field design, motor load, and motor size and construction can all influence the efficiency of a DC motor. By considering and optimizing these factors, the overall efficiency of the motor can be improved.

Where can individuals find reliable resources for learning more about DC motors and their applications?

Individuals seeking reliable resources to learn more about DC (Direct Current) motors and their applications can explore various sources that provide comprehensive and accurate information. Here’s a detailed explanation of where individuals can find reliable resources for learning about DC motors:

1. Manufacturer Websites:

Many DC motor manufacturers have dedicated sections on their websites that provide detailed information about their products, including specifications, application notes, technical guides, and whitepapers. These resources offer valuable insights into the design, operation, and application considerations of DC motors. Examples of reputable DC motor manufacturers include Baldor, Maxon Motor, and Faulhaber.

2. Industry Associations and Organizations:

Industry associations and organizations related to electrical engineering, automation, and motor technology can be excellent sources of reliable information. Examples include the Institute of Electrical and Electronics Engineers (IEEE) and the American Society of Mechanical Engineers (ASME). These associations often provide access to technical publications, research papers, conferences, and educational resources related to DC motors and their applications.

3. Technical Books and Publications:

Technical books and publications authored by experts in the field of electrical engineering and motor technology can provide in-depth knowledge about DC motors. Books such as “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and “Practical Electric Motor Handbook” by Irving Gottlieb are widely regarded as reliable resources for learning about DC motors and their applications.

4. Online Educational Platforms:

Online educational platforms offer a wealth of resources for learning about DC motors. Websites like Coursera, Udemy, and Khan Academy provide online courses, tutorials, and video lectures on electrical engineering, motor theory, and applications. These platforms often have courses specifically dedicated to DC motors, covering topics such as motor principles, control techniques, and practical applications.

5. Research Papers and Scientific Journals:

Research papers published in scientific journals and conference proceedings can provide detailed insights into the latest advancements and research findings related to DC motors. Platforms like IEEE Xplore, ScienceDirect, and Google Scholar can be used to search for scholarly articles on DC motors. These papers are authored by researchers and experts in the field and provide reliable and up-to-date information on various aspects of DC motor technology.

6. Online Forums and Communities:

Online forums and communities focused on electrical engineering, motor technology, and DIY projects can be valuable resources for learning about DC motors. Platforms like Reddit, Stack Exchange (Electrical Engineering section), and specialized motor forums provide opportunities to ask questions, engage in discussions, and learn from experienced individuals in the field. However, it’s important to verify information obtained from online forums as they may contain a mix of opinions and varying levels of expertise.

When accessing these resources, it’s essential to critically evaluate the information and cross-reference it with multiple sources to ensure accuracy and reliability. By utilizing a combination of manufacturer websites, industry associations, technical books, online educational platforms, research papers, and online communities, individuals can gain a comprehensive understanding of DC motors and their applications.

editor by CX 2024-05-07

China 573S15-L 573S09-L High Torque 1.5Nm 3 Phase Stepper Motor for Stepper Motor Nema23 wholesaler

Warranty: 1 yr, Other, 1 Yr

Design Amount: 573S15-L/ 573S09, 573S15-L

Phase: 3

Current / Stage: 5.8A

place accuracy: 5%

Amount of wires: six

Certification: RoHS

Kind: Hybrid

Solution identify: Nema 23 Stepper Motor

Weight: 1.1kg

Packaging Details: picket box

Item OVERVIEW 573S15-L 573S09 High Torque 1.5Nm 3 Phase Stepper Motor for StepperMotor Nema23 Specialized Draws EXHIBITION CERTIFICATIONS Business Details PAYMENT ASSURANCE FAQ What about the guide time and cargo?A: Standard ( common product ) can be ship within 2 working day, Shaft Collar Hex twelve Inch Bore twelve In One particular-Piece bulk get can be sent within ten~35 days. For delivery, we often use DHL, FedEx, UPS, Most affordable Costs Large Responsibility CNC Machined Components For Sale Large Quality Material Manufactured Manufacture in India By Exporters and TNT. For bulk buy, we recommend to send out merchandise by Air or by Sea to conserve your transportation cost.What is the guarantee for your Stepper Motor?A: 1~2 several years primarily based on distinct series.What is your payment phrases?A: We settle for spend by means of Lender Transfer, Paypal, Western Union and Trade Assurance.

Benefits of a Planetary Motor

Besides being one of the most efficient forms of a drive, a Planetary Motor also offers a great number of other benefits. These features enable it to create a vast range of gear reductions, as well as generate higher torques and torque density. Let’s take a closer look at the benefits this mechanism has to offer. To understand what makes it so appealing, we’ll explore the different types of planetary systems.

Solar gear

The solar gear on a planetary motor has two distinct advantages. It produces less noise and heat than a helical gear. Its compact footprint also minimizes noise. It can operate at high speeds without sacrificing efficiency. However, it must be maintained with constant care to operate efficiently. Solar gears can be easily damaged by water and other debris. Solar gears on planetary motors may need to be replaced over time.

A planetary gearbox is composed of a sun gear and two or more planetary ring and spur gears. The sun gear is the primary gear and is driven by the input shaft. The other two gears mesh with the sun gear and engage the stationary ring gear. The three gears are held together by a carrier, which sets the spacing. The output shaft then turns the planetary gears. This creates an output shaft that rotates.

Another advantage of planetary gears is that they can transfer higher torques while being compact. These advantages have led to the creation of solar gears. They can reduce the amount of energy consumed and produce more power. They also provide a longer service life. They are an excellent choice for solar-powered vehicles. But they must be installed by a certified solar energy company. And there are other advantages as well. When you install a solar gear on a planetary motor, the energy produced by the sun will be converted to useful energy.

A solar gear on a planetary motor uses a solar gear to transmit torque from the sun to the planet. This system works on the principle that the sun gear rotates at the same rate as the planet gears. The sun gear has a common design modulus of -Ns/Np. Hence, a 24-tooth sun gear equals a 3-1/2 planet gear ratio. When you consider the efficiency of solar gears on planetary motors, you will be able to determine whether the solar gears are more efficient.

Sun gear

The mechanical arrangement of a planetary motor comprises of two components: a ring gear and a sun gear. The ring gear is fixed to the motor’s output shaft, while the sun gear rolls around and orbits around it. The ring gear and sun gear are linked by a planetary carrier, and the torque they produce is distributed across their teeth. The planetary structure arrangement also reduces backlash, and is critical to achieve a quick start and stop cycle.

When the two planetary gears rotate independently, the sun gear will rotate counterclockwise and the ring-gear will turn in the same direction. The ring-gear assembly is mounted in a carrier. The carrier gear and sun gear are connected to each other by a shaft. The planetary gears and sun gear rotate around each other on the ring-gear carrier to reduce the speed of the output shaft. The planetary gear system can be multiplied or staged to obtain a higher reduction ratio.

A planetary gear motor mimics the planetary rotation system. The input shaft turns a central gear, known as the sun gear, while the planetary gears rotate around a stationary sun gear. The motor’s compact design allows it to be easily mounted to a vehicle, and its low weight makes it ideal for small vehicles. In addition to being highly efficient, a planetary gear motor also offers many other benefits.

A planetary gearbox uses a sun gear to provide torque to the other gears. The planet pinions mesh with an internal tooth ring gear to generate rotation. The carrier also acts as a hub between the input gear and output shaft. The output shaft combines these two components, giving a higher torque. There are three types of planetary gearboxes: the sun gear and a wheel drive planetary gearbox.

Planetary gear

A planetary motor gear works by distributing rotational force along a separating plate and a cylindrical shaft. A shock-absorbing device is included between the separating plate and cylindrical shaft. This depressed portion prevents abrasion wear and foreign particles from entering the device. The separating plate and shaft are positioned coaxially. In this arrangement, the input shaft and output shaft are rotated relative to one another. The rotatable disc absorbs the impact.

Another benefit of a planetary motor gear is its efficiency. Planetary motor gears are highly efficient at transferring power, with 97% of the input energy being transferred to the output. They can also have high gear ratios, and offer low noise and backlash. This design also allows the planetary gearbox to work with electric motors. In addition, planetary gears also have a long service life. The efficiency of planetary gears is due in part to the large number of teeth.

Other benefits of a planetary motor gear include the ease of changing ratios, as well as the reduced safety stock. Unlike other gears, planetary gears don’t require special tools for changing ratios. They are used in numerous industries, and share parts across multiple sizes. This means that they are cost-effective to produce and require less safety stock. They can withstand high shock and wear, and are also compact. If you’re looking for a planetary motor gear, you’ve come to the right place.

The axial end surface of a planetary gear can be worn down by abrasion with a separating plate. In addition, foreign particles may enter the planetary gear device. These particles can damage the gears or even cause noise. As a result, you should check planetary gears for damage and wear. If you’re looking for a gear, make sure it has been thoroughly tested and installed by a professional.

Planetary gearbox

A planetary motor and gearbox are a common combination of electric and mechanical power sources. They share the load of rotation between multiple gear teeth to increase the torque capacity. This design is also more rigid, with low backlash that can be as low as one or two arc minutes. The advantages of a planetary gearmotor over a conventional electric motor include compact size, high efficiency, and less risk of gear failure. Planetary gear motors are also more reliable and durable than conventional electric motors.

A planetary gearbox is designed for a single stage of reduction, or a multiple-stage unit can be built with several individual cartridges. Gear ratios may also be selected according to user preference, either to face mount the output stage or to use a 5mm hex shaft. For multi-stage planetary gearboxes, there are a variety of different options available. These include high-efficiency planetary gearboxes that achieve a 98% efficiency at single reduction. In addition, they are noiseless, and reduce heat loss.

A planetary gearbox may be used to increase torque in a robot or other automated system. There are different types of planetary gear sets available, including gearboxes with sliding or rolling sections. When choosing a planetary gearset, consider the environment and other factors such as backlash, torque, and ratio. There are many advantages to a planetary gearbox and the benefits and drawbacks associated with it.

Planetary gearboxes are similar to those in a solar system. They feature a central sun gear in the middle, two or more outer gears, and a ring gear at the output. The planetary gears rotate in a ring-like structure around a stationary sun gear. When the gears are engaged, they are connected by a carrier that is fixed to the machine’s shaft.

Planetary gear motor

Planetary gear motors reduce the rotational speed of an armature by one or more times. The reduction ratio depends on the structure of the planetary gear device. The planetary gear device has an output shaft and an armature shaft. A separating plate separates the two. The output shaft moves in a circular pattern to turn the pinion 3. When the pinion rotates to the engagement position, it is engaged with the ring gear 4. The ring gear then transmits the rotational torque to the armature shaft. The result is that the engine cranks up.

Planetary gear motors are cylindrical in shape and are available in various power levels. They are typically made of steel or brass and contain multiple gears that share the load. These motors can handle massive power transfers. The planetary gear drive, on the other hand, requires more components, such as a sun’s gear and multiple planetary gears. Consequently, it may not be suitable for all types of applications. Therefore, the planetary gear drive is generally used for more complex machines.

Brush dusts from the electric motor may enter the planetary gear device and cause it to malfunction. In addition, abrasion wear on the separating plate can affect the gear engagement of the planetary gear device. If this occurs, the gears will not engage properly and may make noise. In order to prevent such a situation from occurring, it is important to regularly inspect planetary gear motors and their abrasion-resistant separating plates.

Planetary gear motors come in many different power levels and sizes. These motors are usually cylindrical in shape and are made of steel, brass, plastic, or a combination of both materials. A planetary gear motor can be used in applications where space is an issue. This motor also allows for low gearings in small spaces. The planetary gearing allows for large amounts of power transfer. The output shaft size is dependent on the gear ratio and the motor speed.

editor by czh 2023-02-16

China supplier 3 phase ac induction motor electric motor 7.5kw 10kw 45kw 55kw 75kw 90kw 120kw 185kw 200kw 220kw 250kw 280kw 315kw 400kw 450kw with Good quality

Warranty: 12 months

Model Number: YE2 series motor

Type: Induction Motor

Frequency: 50/60Hz

Phase: Three-phase

Protect Feature: IP54/IP55/IP56/IP65

AC Voltage: 230v 380v 415v 440v 660v 1000v 1140v

Efficiency: IE 2

Place of origin: ZheJiang ,china

Speed: 450-3000rpm

Poles: 2P/4P/6P/8P/As required

Mounting: B3, B5, B35, V1,V3,etc

Insulation class: B/F

Altitude: less than 1000m

Color: Blue/Grey/Green/Required

Usage: Machinery/Mine/Pump/Oil/Chemical/Coal/Air Compressor

Housing: Aluminum Housing Motor

Winding: 100% Cooper Wire

Certification: CCC, ce, ISO9001

Packaging Details: plywood case

Port: HangZhou/ZheJiang /HangZhou

3 phase ac induction motor electric motor 7.5kw 10kw 45kw 55kw 75kw 90kw 120kw 185kw 200kw 220kw 250kw 280kw 315kw 400kw 450kw

Our advantages on 3 phase motor:

1).62 years of 3 phase motor production experience.

2).CCC,CE,Explosion-proof certificate, Mining product safety mark certificate for explosion-proof motor.

3).30,000 sets 3 phase motor were sold last year.

4).All models of 3 phase motor like:YBZ/YB3/YBX3/YBK3,IE2/IE3/IE4,YZS/YZO/YZU/YZUL,MVG/MVE,YVP/YVF/YLJ/YEJ.etc.

5).Adequate stocks for motor.

6).Support customization.

Brand NameYUTONGModel NumberY/Y2/YE2/YE3/YE4/IE2/IE3/IE4 3 phase high efficiency motorVoltage220V/380V/400V/415V/500V/525V/CustomizedEfficiencyIE2/IE3/IE4FrameNodular cast iron or aluminumApplicationWidely used in industry, agriculture, oilfield chemical industry, road construction, mining and other industries to provide power for water pumps, fans, air compressors. It can also be used in metallurgy and food machinery industries. Which is air compressors, refrigerators, mining machinery, reducers, pumps, fans, etc The ideal supporting power for the industry.ZheJiang CZPT Electric Motor Shares Company can design various motors with different frequencies and voltage requirements for users.

3 phase ac induction motor electric motor 7.5kw 10kw 45kw 55kw 75kw 90kw 120kw 185kw 200kw 220kw 250kw 280kw 315kw 400kw 450kw have the advantages of reasonable design, beautiful appearance, high efficiency, low noise and vibration, and high starting torque. The motor protection grade is IP55, the insulation grade is F grade, and the cooling method is IC411. The motor installation size conforms to the IEC standard and can be used with various types of machinery at home and abroad.

Product Parameter Our ServicesPre-sale services:

1. Multiple models to choose.

2. Customized products according to your requests.

3. Professional technicians at your side any time.

Services during the sale:

1. Pre-check and safeguard products before delivery.

2. Provide solutions for any possible problems occured.

After-sale services:

1. warranty:13 months for the machine (not including wearing parts) after delivery.

2. Provide installation files, technical data and related soft copies or videos etc to ensure customer could install and debug by yourselves.

24-hour Services.

Contact us if youhave any questions

Certifications

Visit and Exhibition

Company Information ZheJiang YuTong Motor Shares Company is 1 of the biggest motor manufacturers in China, which owns over 30 years experience in motor production. YuTong owns perfect production technology, scientific quality testing method, strict management system and high efficient staff incentives, which has passed ISO9001 and has obtained CCC, CE and China Energy Conservation Product Certification. We provide a wide range of products, such as YE2 and YE3 series high efficient 3 phase induction motor,YB3, YBK2, series explosion-proof motor, YZS, YZO, TZDC, YZUL series vibration motor,YCT series magnetic speed variable motor, YE2VP series frequency variable motor, YD series multi-speed and Y2EJ, YLJ series special use motor, YLJ series torque motor, GEARBOX motor etc., totally more than 20 series and 400 specifications.These motors are mainly used in machinery, chemicals, papermaking, mining and other industry equipment drive. Also, we can offer special motor according to clients’ requirements and our products can match European IEC standard. Our clients are over the world. We have been operating with ABB, EMERSON, State Grid Corporation of China, Coral-I Solutions, EBARA Corporation and so on.

Recommend Products

FAQIf you are interested in our high quanlity IE2,IE3 series motor

you can offer these information as follows.

Q1: How to choose the suitable electric motor?

A: 1. The type of motor:horizontal(B3) or vertical(B5) vibrating motor.Or you can tell me what equipment you use it for,we can recommand for you.2. The power and speed

3.voltage and frequency

Q2: Can the motor voltage and machine color be changed?

A: Yes,we can change the voltage and colors according to your reference

Q3: How long is the warranty period for your equipment?

A: Our machine has 13 months guarantee. During the guarantee period, if any quality problems occur, we will provide the related spare parts(consumable spare parts not included freight free of charge.

Q4: What is the price term and payment method?

A: We can quote EXW, FOB, CIF and CFR price. You can pay us by T/T, L/C , Visa.

The Basics of a Gear Motor

The basic mechanism behind the gear motor is the principle of conservation of angular momentum. The smaller the gear, the more RPM it covers and the larger the gear, the more torque it produces. The ratio of angular velocity of two gears is called the gear ratio. Moreover, the same principle applies to multiple gears. This means that the direction of rotation of each adjacent gear is always the opposite of the one it is attached to.

Induction worm gear motor

If you’re looking for an electric motor that can deliver high torque, an Induction worm gear motor might be the right choice. This type of motor utilizes a worm gear attached to the motor to rotate a main gear. Because this type of motor is more efficient than other types of motors, it can be used in applications requiring massive reduction ratios, as it is able to provide more torque at a lower speed.

The worm gear motor is designed with a spiral shaft that is set into splines in another gear. The speed at which the worm gear rotates is dependent on the torque produced by the main gear. Induction worm gear motors are best suited for use in low-voltage applications such as electric cars, renewable energy systems, and industrial equipment. They come with a wide range of power-supply options, including twelve-volt, 24-volt, and 36-volt AC power supplies.

These types of motors can be used in many industrial settings, including elevators, airport equipment, food packaging facilities, and more. They also produce less noise than other types of motors, which makes them a popular choice for manufacturers with limited space. The efficiency of worm gearmotors makes them an excellent choice for applications where noise is an issue. Induction worm gear motors can be compact and extremely high-torque.

While the Induction worm gear motor is most widely used in industrial applications, there are other kinds of gearmotors available. Some types are more efficient than others, and some are more expensive than others. For your application, choosing the correct motor and gearbox combination is crucial to achieving the desired result. You’ll find that the Induction worm gear motor is an excellent choice for many applications. The benefits of an Induction worm gear motor can’t be overstated.

The DC gear motor is an excellent choice for high-end industrial applications. This type of gearmotor is smaller and lighter than a standard AC motor and can deliver up to 200 watts of torque. A gear ratio of three to two can be found in these motors, which makes them ideal for a wide range of applications. A high-quality DC gear motor is a great choice for many industrial applications, as they can be highly efficient and provide a high level of reliability.

Electric gear motors are a versatile and widely used type of electric motor. Nevertheless, there are some applications that don’t benefit from them, such as applications with high shaft speed and low torque. Applications such as fan motors, pump and scanning machines are examples of such high-speed and high-torque demands. The most important consideration when choosing a gearmotor is its efficiency. Choosing the right size will ensure the motor runs efficiently at peak efficiency and will last for years.

Parallel shaft helical gear motor

The FC series parallel shaft helical gearmotor is a compact, lightweight, and high-performance unit that utilizes a parallel shaft structure. Its compact design is complemented by high transmission efficiency and high carrying capacity. The motor’s material is 20CrMnTi alloy steel. The unit comes with either a flanged input or bolt-on feet for installation. Its low noise and compact design make it an ideal choice for a variety of applications.

The helical gears are usually arranged in two rows of one another. Each row contains one or more rows of teeth. The parallel row has the teeth in a helical pattern, while the helical rows are lined up parallelly. In addition to this, the cross helical gears have a point contact design and do not overlap. They can be either parallel or crossed. The helical gear motors can have any number of helical pairs, each with a different pitch circle diameter.

The benefits of the Parallel Shaft Helical Gearbox include high temperature and pressure handling. It is produced by skilled professionals using cutting-edge technology, and is widely recognized for its high performance. It is available in a range of technical specifications and is custom-made to suit individual requirements. These gearboxes are durable and low-noise and feature high reliability. You can expect to save up to 40% of your energy by using them.

The parallel shaft helical gear motors are designed to reduce the speed of a rotating part. The nodular cast iron housing helps make the unit robust in difficult environments, while the precision-machined gears provide quiet, vibration-free operation. These motors are available in double reduction, triple reduction, and quadruple reduction. The capacity ranges from 0.12 kW to 45 kW. You can choose from a wide variety of capacities, depending on the size of your gearing needs.

The SEW-EURODRIVE parallel shaft helical gearmotor is a convenient solution for space-constrained applications. The machine’s modular design allows for easy mounting and a wide range of ambient temperatures. They are ideal for a variety of mechanical applications, including conveyors, augers, and more. If you want a small footprint, the SEW-EURODRIVE parallel shaft helical gear motor is the best solution for you.

The parallel shaft helical gears are advantageous for both high and low speed applications. Parallel helical gears are also suitable for low speed and low duty applications. A good example of a cross-helix gear is the oil pump of an internal combustion engine. Both types of helical gears are highly reliable and offer vibration-free operation. They are more costly than conventional gear motors, but offer more durability and efficiency.

Helical gear unit

This helical gear unit is designed to operate under a variety of demanding conditions and can be used in a wide range of applications. Designed for long life and high torque density, this gear unit is available in a variety of torques and gear ratios. Its design and construction make it compatible with a wide range of critical mechanical systems. Common applications include conveyors, material handling, steel mills, and paper mills.

Designed for high-performance applications, the Heidrive helical gear unit provides superior performance and value. Its innovative design allows it to function well under a wide range of operating conditions and is highly resistant to damage. These gear motors can be easily combined with a helical gear unit. Their combined power output is 100 Nm, and they have a high efficiency of up to 90%. For more information about the helical gear motor, contact a Heidrive representative.

A helical gear unit can be classified by its reference section in the standard plane or the turning plane. Its center gap is the same as that of a spur gear, and its number of teeth is the same. In addition to this, the helical gear has a low axial thrust, which is another important characteristic. The helical gear unit is more efficient at transferring torque than a spur gear, and it is quieter, too.

These units are designed to handle large loads. Whether you are using them for conveyors, augers, or for any other application that involves high-speed motion, a helical gear unit will deliver maximum performance. A helical gear unit from Flender can handle 400,000 tasks with a high degree of reliability. Its high efficiency and high resistance to load ensures high plant availability. These gear motors are available in a variety of sizes, from single-speed to multi-speed.

PEC geared motors benefit from decades of design experience and high quality materials. They are robust, quiet, and offer excellent performance. They are available in multiple configurations and are dimensionally interchangeable with other major brands. The gear motors are manufactured as modular kits to minimize inventory. They can be fitted with additional components, such as backstops and fans. This makes it easy to customize your gear motors and save money while reducing costs.

Another type of helical gears is the double helical gear. The double helical gear unit has two helical faces with a gap between them. They are better for enclosed gear systems as they provide greater tooth overlap and smoother performance. Compared to double helical gears, they are smaller and more flexible than the Herringbone type. So, if you’re looking for a gear motor, a helical gear unit may be perfect for you.

in Ar-Rusayfah Jordan sales price shop near me near me shop factory supplier 3 Phase 25W Induction Electric AC Gear Motor manufacturer best Cost Custom Cheap wholesaler

The substantial exact CNC equipment, this kind of as Sluggish-feeding wire-reduce device, jig grinding equipment and electric powered discharge machine, ensures the best good quality precision of mould processing, with the substantial successful and environmental security acid rolling line currently being the greatest uncooked substance changing gear in the discipline in china The wildly use of automated milling machine, substantial-speed automatic feeding punch, higher velocity automated rolling and assembling device assures the large top quality and performance of elements and chain producing. Our professionals and engineers have 23 many years of Expertise in the Bearing Market. With thorough requirments, we can also build your particular designed product.

Requirements

1) Dimensions of gadget: 42mm, 60mm, 70mm, 80mm, 90mm, 104mm

two) EPT: 6W, 15W, 25W, 40W, 60W, 90W, 120W, 140W

three) Voltage Poles: Single-Phase 100V fifty/60Hz 4P

Solitary-Section 110V fifty/60Hz 2P

One-Period 110V fifty/60Hz 4P

One-Stage 110V 50/60Hz 2P

Single-Phase 110V,120V 60Hz 4P

Single-Period 220V,120V 60Hz 4P

3-Period two hundred/220/230V fifty/60Hz 4P

3-Phase 380/415V 50/60Hz 4P

Three-Stage two hundred/220/230V 50/60Hz 2P

A few-Section 380/415V 50/60Hz 2P

four) Equipment ratio of the Equipment Head: three, three.six, five, six, seven.five, 9, 12.five, fifteen, 18, twenty five, 30, 36, fifty, sixty,seventy five,90,100,120,150,a hundred and eighty,250

We are EPTized in Mini AC Equipment Motor. Our major goods are used for EPTTools, Textile EPTry, Health-related Equipment, Conveying EPT, Printing Mechanism, Meals EPTry, Vending EPT, EPT EPTry, Gumming EPT and so on. We offer consumers with top quality items and fantastic service. Remember to get in touch with us if you have any concern or inquiry.

Our reduction geared motor Advantage

1,reasonable price tag with excellent high quality

2,supply in time

three,safe ,trustworthy ,economical and resilient

4,steady EPT ,silent operation

five,smooth working and lower sounds

six,good physical appearance ,tough services lifestyle

seven,substantial heat-radiating effectiveness ,large carrying capacity

eight,every EPT need to be analyzed before EPT

nine.reply in substantial performance during a single operating working day

ten. expert to make EPT and electric powered motor .

FAQ

one, Q:what is actually your MOQ for ac EPT motor ?

A: 1pc is okay for each and every type electric powered gear box motor

two, Q: What about your warranty for your induction velocity EPT motor ?

A: 1 calendar year ,but besides male-manufactured wrecked

3, Q: which payment way you can take ?

A: TT, western union .

four, Q: how about your payment way ?

A: one hundred%payment EPTd considerably less $5000 ,thirty% payment EPTd payment , 70% payment just before sending in excess of $5000.

five, Q: how about your EPT of velocity reduction motor ?

A: plywood circumstance ,if measurement is small ,we will pack with pallet for less 1 container

six, Q: What information should be given, if I get electric helical geared motor from you ?

A: rated EPT, ratio or output speed,sort ,voltage , mounting way , amount , if more is greater ,

in Cali Colombia sales price shop near me near me shop factory supplier Yvfz 3 Phase Induction 900kw Speed Variable AC Motor manufacturer best Cost Custom Cheap wholesaler

Every method, every part, each purpose in EPG is demanded to be completed one action following an additional, carefully and cautiously, from substance selection, reformation to manufacturing components, from elements warmth remedy to computerized assembly, from high quality manage to merchandise inspection and tests and from purchase working to following revenue service. Superior thermo treatment products, these kinds of as network warmth treatment method oven, multi-use thermo treatment method oven, and so forth. a specialized supplier of a total variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers. 1 periodmotor specifications colon

| Electric Inducation ac motor | ||||||||

| Rated Voltage | colon 380V lpar 400V comma 660V comma 690V are also obtainable on ask for rpar | |||||||

| Rated frequency | 60 comma 50Hz | |||||||

| EPT torque | Output is in the range of rated frequency to 50Hz | |||||||

| Insulation | F or H class | |||||||

| Cooling sort | IC416 | |||||||

| Safety Class | IP54 commaIP55 commaIP56 semi | |||||||

| Mounting kind | IMEPT3 lparor as requested rpar | |||||||

| Functioning Styles | S1 lparS3-25 percnt semi S3-60 percnt are accessible rpar | |||||||

| Motor Body Measurement | 355 semi400 comma450 comma500 comma560mm | |||||||

two periodTypical apps

Pumps

Followers and Pumps

Crushers

Conveyor belts

Mills

Centrifugal EPTs

Presses

Lathe

Elevators

EPT tools

Grinders and other individuals

Rubber mixer and plastic extruder

three periodOur Power colon

Additionally comma in orEPTto distinguish us from competition comma to expand even more and acquire much more industry share comma we decided to make investments most of its earnings in EPTizing and obtained the quality certification of ISO9001 comma passed CE periodAt the exact same time we has dozens of UEPTty Product Patents period of time We also produced a cooperation with ZheJiang Electrical Equipment Research Institute lparGroup rpar Co interval commaLtd comma as EPT motor creation base for SEARI in 2005 period of time Now participates in numerous international tenders and exports to several international locations all around the planet by means of everyone aposs endeavours in Hengli time period

4 periodProduction of method colon

We strictly verify on each phase of the production chain to make sure backlinks is very good in high quality comma to satisfy consumers apos need and ensure shipping and delivery at the exact same time period superior products and total inside offer chain comma from punching comma laminating comma welding comma machining comma winding comma embedded line comma dipping comma assembled to test comma all the techniques are done in-home to ensure top quality time period

five periodWarranty Period of time colon

The motor could perform properly inside one year aposs making use of time period or no considerably less than 13 months from departure date of our firm lparsubject to the very first rpar if the user use and store the motor properly in accordance to the instruction period of time

If the motor is broken or can not work usually inside of the stipulated time owing to the poor top quality comma our organization will mend and exchange the spare parts or motors free of charge of cost commawhile all entry and eXiHu (West Lake) Dis.t charges borne by the purchaser period of time

six periodService after the Warranty Interval colon

Our organization implements the lifeEPT paid out service if malfunction takes place after the guarantee period comma we will provide the needed effortless-weared parts and spare elements at value price interval Following revenue- support staff will call back the user irregularly time period

in Makassar Indonesia sales price shop near me near me shop factory supplier B35 Installation Method 3 Phase Electric Pm AC Motor manufacturer best Cost Custom Cheap wholesaler

Obtaining amassed valuable knowledge in cooperating with foreign customers, With several years’ expertise in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time shipping, prompt responses, on-hand engineering assist and very good soon after-income providers. Every approach, each and every segment, every single purpose in EPG is demanded to be completed a single stage subsequent an additional, very carefully and cautiously, from material assortment, reformation to production components, from factors heat remedy to computerized assembly, from quality manage to item inspection and tests and from get working to right after product sales support. EPT35 Installation Approach 3 Period Electric powered PM AC Motor

Item Function

1.Suitable for the 5100rpm large velocity

two.Substantial EPT amp high torque

3.Higher effectiveness

four.Modest size

five.Reduced sound low vibration

6.PatEPTd cooling construction

7.Easy routine maintenance and EPT existence time

8.Effective CoaXiHu (West Lake) Dis.al Fan

Requirements

Design type: SRPM314L8X135

Voltage: 380V AC

Rated EPT: 135KW

Rate Torque : 253N.m

Operating pace: 5100rpm

Effectiveness: ninety seven.five%

Services Factor: 1.two

Isolation: H/F

H2o/dust Evidence: IP54

Pole Quantity: 8

Cooling Method: Air

Placement Signal: Resolver (optional)

Set up Strategy: EPT35

Software

Followers,Pumps,Compressors

Other Designs you will be fascinated in:

| Motor type | Voltage (V AC) |

Rated EPT (kW) |

Rated torque (N.m) | Rated velocity (rpm) |

Effectiveness (%) |

Provider Factor | Insulation | Ingress protection | Pole Amount | Fat (kg) |

Cooling Strategy | Situation Sign | Set up Approach |

| SRPM205L8XF18.five | 380 | eighteen.five | 35.3 | 5000 | ninety six | one.two | H/F | IP54 | 8 | 38 | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF22 | 380 | 22 | 36.3 | 5800 | 96 | one.2 | H/F | IP54 | 8 | forty one | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF30 | 380 | thirty | 49.4 | 5800 | 96.1 | one.2 | H/F | IP54 | 8 | 46 | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF37 | 380 | 37 | fifty five | 6500 | 96.three | one.two | H/F | IP54 | eight | fifty | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF45 | 380 | 45 | sixty six.1 | 6500 | 96.3 | one.2 | H/F | IP54 | eight | seventy six | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF55 | 380 | fifty five | 80.8 | 6500 | ninety six.3 | one.2 | H/F | IP54 | 8 | 85 | Air Cooling | Resolver | EPT35 |

| SRPM205L8XF75 | 380 | seventy five | one hundred ten | 6500 | 96.5 | one.two | H/F | IP54 | eight | 97 | Air Cooling | Resolver | EPT35 |

| SRPM314L8X135 | 380 | one hundred thirty five | 253 | 5100 | 97.five | 1.two | H/F | — | eight | — | Refrigerant | Resolver | — |

FAQ

1.Do you provide the samples?

Of course. Our organization can give the samples to you.

2.What is your MOQ

Only 1 Computer.

three.Can your business personalize the solution in accordance to my demands?

Sure.Our firm can customise the motor dependent on customer wants.

four.Are you trading firm or company ?

We are a company.

five.Where is your Organization address?

EPTgang District HangZhou EPT

in Kampala Uganda sales price shop near me near me shop factory supplier 8 Poles IP54 3 Phase AC Servo Synchronous Permanent Magnet Motor manufacturer best Cost Custom Cheap wholesaler

Our products are made by modern day computerized equipment and gear. The new items consist of a collection of higher-tech and large top quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator phase-chains, higher-pace tooth chains, timing chains, self-lubrication chains, between which have sort high speed tooth chain for automobile department dynamic box and aerial chains fill in the blanks of chain in China. EPG was awarded with “well-known product of Zhejiang Province” and “popular model of Zhejiang Province”. 8 Poles IP54 3 Period AC Servo Synchronous Long term Magnet Motor

Solution Feature

| one | higher velocity range from 6000rpm-8000rpm |

| two | Higher EPT amp large torque |

| three | Substantial effectiveness |

| four | Little dimensions |

| five | Reduced sound reduced vibration |

| 6 | PatEPTd cooling composition |

| seven | Straightforward routine maintenance and EPT existence time |

| 8 | For both water / oil cooling possibilities |

Specifications

| Motor kind | Voltage (V AC) |

Rated EPT (kW) |

Rated torque (N.m) | Rated pace (rpm) |

Performance (%) |

Service Element | Insulation | Ingress protection | Pole Number | Fat (kg) |

Cooling Approach | Position Signal | Installation Strategy |

| SRPM200L8XW37 | 380 | 37 | sixty | 6000 | ninety six.three | one.2 | H/F | IP54 | 8 | forty five | Oil/Drinking water Cooled | Resolver (optional) |

EPT35 |

Application

High-pace Compressors,Supporters,Pumps

About MC Motor

MC Motor EPT Co., Ltd is a leading higher-tech EPTrprises which focuses on the design and style, analysis and manufacture of the new era large speed long lasting magnet motors, which are widely utilised in EPT, agriculture, mining, creating services, water-treatment, automotive and other new rising EPT.

In the past couple of many years, MC Motor prospects a sequence of technological improvements, and created outstanding achievements, incEPTs:

one.Obtains globally reserved mental house rights about approXiHu (West Lake) Dis.mately one hundred main systems, most of which have been efficiently applied to our motors

two.Attained much more than 50 new designed PM higher speed motors from 8KW to 200KW, 5000rpm to 24000rpm, which have significantly larger performance, EPT density, reliability and more compact measurement amp lighter weigEPT than other related PM motor.

three.Varieties mature creation traces and professional amp outstanding groups of management, R ampD, marketing and sales, obtains extremely very good status from our clientele globe-commonly.

MC MOTOR has worldwide stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd QC management method to make confident every single creation procedure strictly complies with ISO9001-2015.

Delivery direction

1. Sample purchase: our stock cargos L/T one~3 times, tailored forty five~60 days

2. Mass manufacturing get: fifteen~twenty five daEPTbased on the amount

3. EPTy air: we usually get DHL/FEDEX/UPS/TNT or other doorway to doorway provider

four. EPTy sea: LCL/FCL are each okay

Payment strategy

one. we settle for T/T, WESTERN UNION, PAYPAL , L/C at sigEPT or ALIEPTAEPTA ASSURANCE

2. 30% deposit, 70% before delivery (Volume more than 5000USD)

| Motor sort | Voltage (V AC) |

Rated EPT (kW) |

Rated torque (N.m) | Rated speed (rpm) |

Efficiency (%) |

Service Element | Insulation | Ingress protection | Pole Number | Bodyweight (kg) |

Cooling Method | Place Signal | Installation Strategy |

| SRPM200M8XW50 | 380 | 50 | sixty | 8000 | ninety six.3 | S1 | H/F | IP54 | 8 | forty five | Oil/Drinking water Cooled | Resolver | EPT35 |

| SRPM220L8XW75 | 380 | 75 | a hundred and twenty | 6000 | 96.five | S1 | H/F | IP54 | eight | 70 | Oil/H2o Cooled | Resolver | EPT35 |

| SRPM220M8XW100 | 380 | 100 | 120 | 8000 | 96.five | S1 | H/F | IP54 | eight | 70 | Oil/H2o Cooled | Resolver | EPT35 |

FAQ

1.Do you offer the samples?

Indeed. Our business can supply the samples to you.

two.What is your MOQ

Only 1 Pc.

three.Can your firm customise the merchandise in accordance to my wants?

Yes.Our company can customize the motor dependent on client requirements.

4.Are you trading firm or company ?

We are a company.

five.Exactly where is your Company handle?

EPTgang District HangZhou EPT

in Villahermosa Mexico sales price shop near me near me shop factory supplier 3 Phase High Efficiency Ie2 Ie3 AC Motor manufacturer best Cost Custom Cheap wholesaler

Because of to our sincerity in supplying greatest services to our consumers, comprehending of your demands and overriding sense of accountability towards filling buying requirements, We can source a entire-range of energy transmission items like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. a specialized supplier of a entire selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers.

YE3 are the substantial-performance series deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed by our business by combing a lot of many years of encounters in the generation of EPT motors of our firm and ZheJiang Electrical Apparatus Analysis Institute, and adopting new systems, processes and materials, in line with the newest vitality performance rate stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds in IEC60034-30 amp GEPT/T18613-2012 and in accordance with quotTest Dedication for Rotating Motor’s Reduction and Effectiveness quot in the next part of IEC60034-two Rotating Motor. Adopting a squirrel-cage construction and insulation class F, the collection has this kind of positive aspects as reputable procedure and maintenance convenience, whose mounting dimension and EPT degree both fulfill stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds of IEC.

Rated EPT: 3~315KW

Rated voltage: 380V/415V/440V/660V

Reference frequency: 50Hz/60HZ

Cooling manner: IC411

Insulation class: F

Strength efficiency score: IE2/IE3

Protection class: IP54/IP55

Environment temperature: -fifteen ordmC~40 ordmC

Altitude: no more than 1,000m

Link mode: Y-connection for the types with a EPT of 3kW or below #9651-link for the kinds with a EPT of 4kW or earlier mentioned

EPTasic structural kind: EPT3, EPT5, EPT35, EPT14, EPT34

Advantages:

1. Novel layout

two. Outstanding starting up overall performance

3. Large beginning torque

4. Reduced noise

5. Little vibration

6. Safe operation

seven. Straightforward upkeep

Principal approach stream of the motor

Motor stator: casing processing #8594 punching push #8594 iron core seating #8594 coil producing #8594 weaving #8594 dipping paint drying

Electronic rotor: blank shaft processing #8594 iron core push installation #8594 iron main cast aluminum #8594 rotor string shaft #8594 weave #8594 dipping paint drying #8594 dynamic equilibrium

Motor assembly: stator rotor assembly #8594 EPT test #8594 motor look coloring #8594 EPT storage

The organization insists on delivering higher-good quality motor items and providers to consumers, and has received high praise from a lot of domestic and international buyers. The business will EPT many international retailers to visit our manufacturing facility each 12 months, and establish a great cooperative relationship via on-site inspection of our manufacturing facility. Our business alwaEPTwelcomes consumers to visit our manufacturing unit.

Why choose us (our service edge)

one. Specialist motor producing service company

two. Audio solution high quality management and certification technique

three. Have a expert income and technological provider staff

four. The motor has perfect approach and strong mechanical processing capacity

five. Higher stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd merchandise technical services program

6, good faith and mutual reward, excellent credit rating ensure.

in Uige Angola sales price shop near me near me shop factory supplier Ys Ms Professional Manufacturing Aluminium Housing 3 Phase High Reliability, Easy Operation AC Electric Motor manufacturer best Cost Custom Cheap wholesaler

Our goods are produced by contemporary computerized machinery and gear. Our specialists and engineers have 23 a long time of Experience in the Bearing Business. Our merchandise range also covers locking assemblies (clamping factors/locking system), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes. WHY Choose US ?

1.We are professional electric powered motor manufacture for thirty years since 1986.

two.We have very best quality supplies to make our electrical motors best overall performance.

three.Our products are 100% cooper wire , a hundred% output.

4.We have superior test EPT to make the one hundred% competent merchandise for our buyers.

five.We have superior winding , portray, assembly and EPT equipments manufacturing line which make our items great visual appeal, good performance and properly packaged.

six.We have superior and automatic EPTs these kinds of as substantial pace punching EPTs, swing punching EPTs, EPTs to type the rotors ,stators and so on. in 1 piece, automatic EPT EPTs which can make wonderful visual appeal and great efficiency motors even though decrease the labor price and mechanical decline .

seven.We have expert finXiHu (West Lake) Dis.Hu (West Lake) Dis.al department who are excellent at calculating and controlling the price and money procedure which could make most favorable costs for our customers.

8,We have wonderful knowledge on OEM and ODM for any band which has trade letter authorization

Our Services

1. Personalized Generation is offered.

two. Supply for OEM and Right after Markets.

three. one hundred% examined for the good quality prior to cargo

4. Certificate and Ensure: ISO 9001:2008,CE / one particular yr

five. deal: carton amppallet

six. IE1 3 stage electric powered motors, cast iron and aluminium frame

seven. IE2 and IE3 cast iron and aluminium body electric powered motors

eight. EPTrake electrical motors

nine. Expostion evidence electric powered motors

ten. aggressive price

eleven. thirty many years producing experience

12. Special motors can be created in accordance to customers’ demands

Att:Our business cost was based mostly on large heigEPT cold rolled steel stator to promise the efficiency ,if you need to have to less expensive ,you can select limited heigEPT stator or sizzling cold rolled steel stator ,thankyou

Merchandise specifics

Software

YS series 3 section asynchronous motor is designed and produced in accordance to the countrywide stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd JEPT/T1009-1991.The eletric motor has the qualities of large efficiency , vitality-saving,reduced sounds,tiny vibration ,EPT services existence,hassle-free servicing and Large beginning.

YS sequence motors are suited for air compressor,cutting EPT,pump,mixer,argriculture EPTry, meals processing EPT,and other equipment requiring large commencing and operating torque.

Thorough Merchandise Description

one.CQC,ce certification

two.Copper wire

three.Chilly-rolled silicon steel sheet

Requirements

one) Centre heigEPT of body :71-90mm

two) EPT variety: .twenty five-2.2kw

three) Rated voltage: 380V or on your ask for

four) Frequency: 50Hz

five) Defense course: IP44

6) Insulation course: EPT

7) Components: Iron

8) Duty sort: S1

Observe: If you have any EPT needs, make sure you get in touch with us.

| Kind | output (kw) |

Existing (A) |

Velocity (rpm) |

Eff % | EPT issue |

Tstart/Tn | Ist/In | Tmax/Tn | |

| YS711-2 | .37 | .ninety five | 2800 | seventy three.five | .80 | two.three | 6 | two.three | |

| YS712-two | .fifty five | one.35 | 2800 | 75.five | .eighty two | two.three | 6 | 2.3 | |

| YS801-two | .seventy five | one.seventy five | 2800 | 76.5 | .85 | two.2 | 6 | two.3 | |

| YS802-2 | one.1 | two.fifty six | 2800 | 77 | .85 | 2.two | six | 2.three | |

| YS90S-2 | one.5 | three.forty four | 2800 | 78.5 | .85 | 2. | 7 | 2.3 | |

| YS90L-2 | two.one | four.84 | 2800 | 81 | .86 | two. | seven | two.3 | |

| YS711-4 | .twenty five | .83 | 1400 | sixty seven | .68 | 2.four | 6 | 2.four | |

| YS712-four | .37 | 1.twelve | 1400 | sixty nine.5 | .seventy two | two.four | 6 | two.four | |

| YS801-4 | .55 | 1.fifty five | 1400 | 73.5 | .73 | 2.3 | six | two.four | |

| YS802-four | .75 | two.01 | 1400 | seventy five.5 | .75 | 2.three | six | two.four | |

| YS90S-four | 1.1 | 2.seventy five | 1400 | 78 | .78 | 2.three | 6.five | 2.4 | |

| YS90L-4 | one.five | 2.01 | 1400 | seventy nine | .79 | two.three | six.5 | two.4 | |

Connection

connection strategy unEPT3KW connection strategy previously mentioned 3KW

Merchandise approach

FAQ

Q1: What about the transport approaches?

1): For urgent orEPTand ligEPT fat, you can choose the adhering to convey: UPS, FedEx, TNT, DHL, EMS.

For large excess weight, you can decide on to supply the items by air or by sea to save cost.

Q2: What about the payment techniques?

A2: We accept T/T, L/C for massive volume, and for tiny amount, you can pay us by PayPal, Western Union and so on.

Q3: How significantly does it value to ship to my place?

A3: It depends on EPTons. Price is different in different EPTons. You can consult us at all moments.

This fall: What is actually your supply time?

A4: Normally we generate inside twenty five-30daEPTafter the payment came.

Q5: Can I print our brand/code/collection amount on your motor?

A5: Yes, of course.

Q6: Can I orEPTsome sample for our testing?

A6: Of course, but it needs some expenditures.

Q7: Can you customize my solution in EPT prerequisite?

A7: Of course, we can offer you OEM.

in Kagoshima Japan sales price shop near me near me shop factory supplier Gphq Y2 15HP CV 11kw Cast Iron 3 Phase Electric AC Motor manufacturer best Cost Custom Cheap wholesaler

We examine each and every piece of bearing by ourselves before shipping. Services & Quality controlWe supply detailed drawings and offer you each time required. The group has taken part in the generating and revising of ISO/TC100 worldwide chain normal a number of many years in accomplishment and hosted the 16th ISO/TC100 Worldwide once-a-year assembly in 2004.

gt Solution Introduction

Gphq Y2/YE2 15HP/CV 11kw Cast Iron 3 Stage Electric AC Motor

Y2/ YE2 Collection Forged Iron Three Phase Induction Motor is EPTly developed for European market place, whose terminal box is positioned on the prime of motor.They are absolutely enclosed and enthusiast-cooling developed. They are freshly designed in conformity with the appropriate demands / policies of IEC stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds.

For the Relationship Model of 2p 4p 6p 8p Y2 motor, please refer to the Identify Plate on the motor (The Y Relationship is adopted by motors’ Output equal or beneath 3kW The Delta-Connection is adopted by motors’ Output previously mentioned 4kW).

| EPT: | .55kw-315kw | Voltage: | 380/415/440V( can can done as your need to have) |

| Frequency: | 50/60hz | Enamelled Wire: | Copper Wire (Can Completed Aluminum wire as Your Need) |

| Insulation Course: | F | Mounting Way: | EPT3 Foot /EPT5 Flange /EPT35 Foot and Flange |

| Protection Quality: | IP55 | motor physique : | solid iron human body of ac motor |

gt Purposes

EPT location and EPT without having EPT requirments, for case in point: EPT instruments, pumps, enthusiasts, transportation EPTry, mixer, agriculture EPTry, foods EPTs, agitator, air compressor and so on. We also can provide aluminum housing kind for frame size unEPTthe stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd of IEC.

gt Our Electric powered Motor Rewards

one. Wonderful good quality of components(Chilly silicon steel/a hundred% copper wire/ Aluminum body)

2.Colourful wiring

three.Clear nameplate

4.Reputable package deal

5.High performance, reduced sound

6.EPTest resources make very best performance

FAQ

one, Q:what is actually your MOQ for ac synchronous motor ?

A: 5pc is okay for each and every variety electrical motor

two, Q: What about your guarantee for your a few period motor?

A: one yr ,but besides male-produced ruined

3, Q: which payment way you can settle for ?

A: TT, western union .

four, Q: how about your payment way ?

A: a hundred%payment EPTd much less $5000 ,30% payment EPTd payment , 70% payment before sending in excess of $5000.

5, Q: how about your EPT of induction motor ?

A: carton or plywood situation ,if much less a single container , we can pack all goods with pallet for small size motor

six, Q: What info must be provided, if I purchase electrical ac motor from you ?

A: rated EPT, speed or pole ,type ,voltage , mounting way , quantity , if much more is greater.